Thèses

Lundi 1er Février 2021 à 9h30.

Micromechanics of Hydrogen Embrittlement of Aluminum Alloys

Leonel STERMANN

(leonel.stermann@univ-lyon1.fr)

Videoconférence

Invité(e) par

Döme TANGUY et Loïc VANEL

présentera en 2 heures :

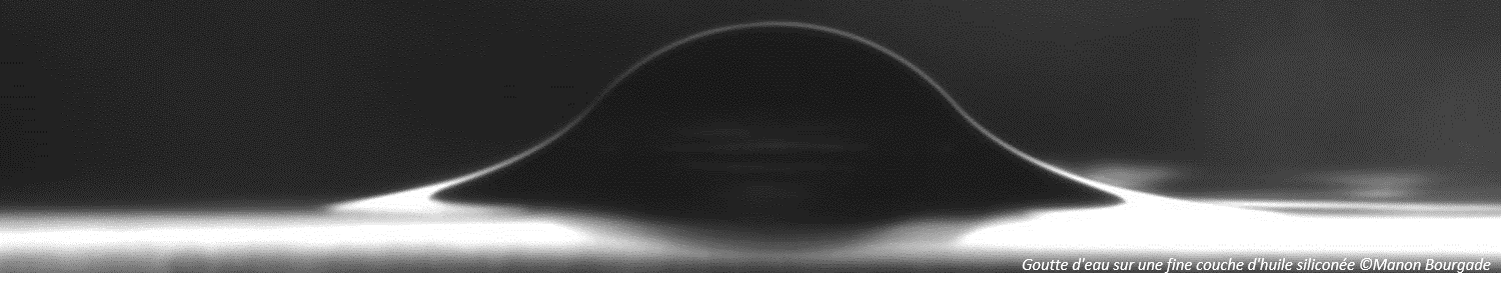

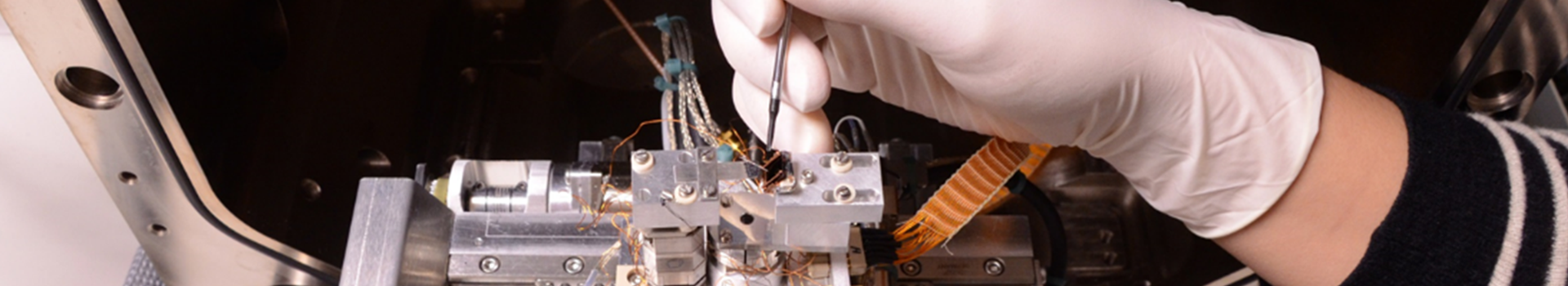

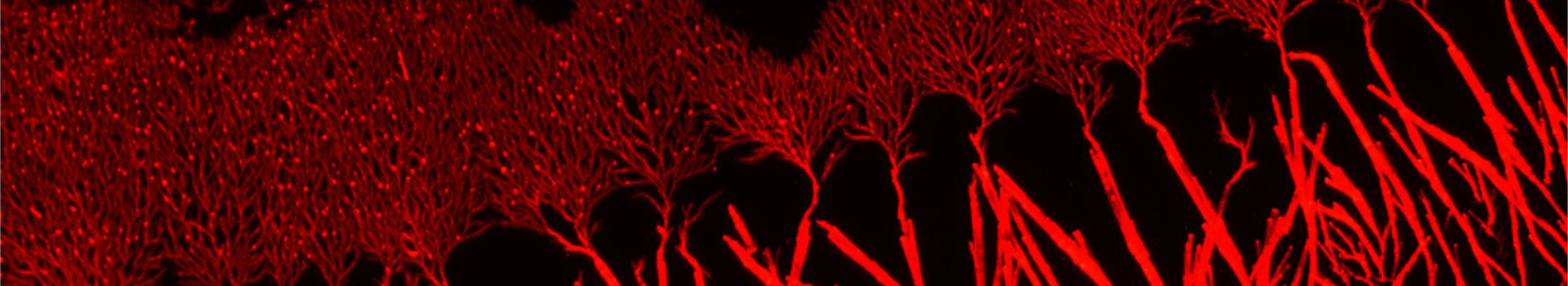

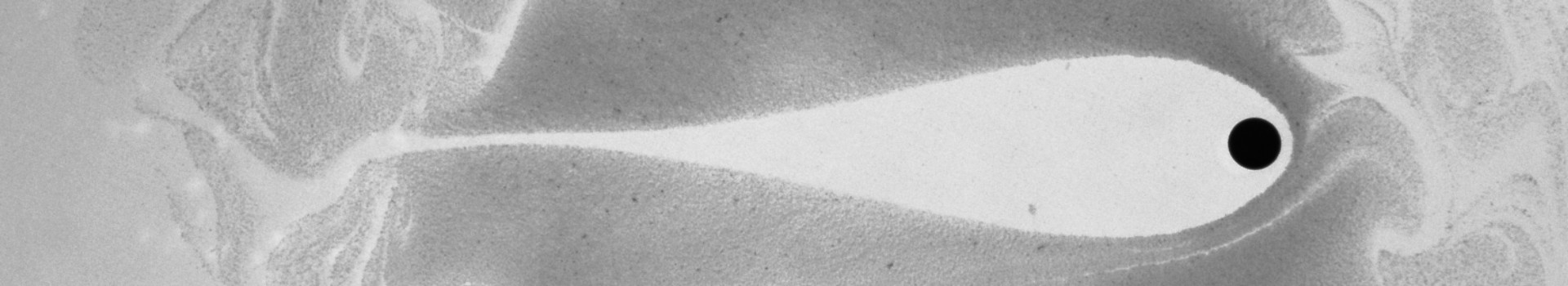

''Hydrogen embrittlement (HE) is a significant concern in the traditional industry and the new ”green” energies and technology. Despite decades of effort in research, it is still not well understood. Sub-grain scale study of the phenomena is a crucial element to understand the process. Our strategy consists of observing crack propagation, at the grain scale, on a commercial aluminum alloy and different hydrogen-assisted cracking conditions. Also, reducing the size of the system by using a micro tensile machine. Hydrogen embrittlement is studied in an AlZnMg alloy (7108 in T4 state). Micro tensile samples are machined along the short transverse direction of a laminated plate. The samples are notched and heat treated. The experimental work aims to study Internal Hydrogen Embrittlement (IHE) and Stress Corrosion Cracking (SCC). For the IHE tests, the sample is electrochemically charged with hydrogen for different charging times and potentials before being placed in the micro tensile machine. For SCC, a microcell, built from a 3D printer, is filled with saline water (free potential), and the sample is mounted

on this setup during the tensile test. Crack propagation is followed on the surface with an optical microscope at high-magnification (x 2000), giving access to fracture and plastic mechanisms at a subgrain size scale. Digital Image Correlation (DIC) is used to measure the surface displacement and strain field and identify the crack tip position. In both conditions (SCC and IHE), two different plasticity kinds were observed accompanying the crack propagation. The first kind is deformation bands emitted from the crack. The second one is an intense deformation just ahead of the crack tip with a few microns extension. Crack propagation velocities are measured and applied Stress Intensity Factor (SIF) values are calculated. Scanning Electron Microscope (SEM) analysis of the fracture surface is correlated with the local propagation velocity in order to match local velocity points with the fracture morphology (e,g, intergranular, transgranular). The accompanying plasticity is quantified by integration of the DIC strain map. Also, incremental crack opening displacement profiles are obtained from the DIC analysis and quantify the involve plasticity. The quantified plasticity in SCC and IHE (PDR and ODR indexes) has a similar range of values. The main difference between SCC and IHE is the range of velocities, being SCC faster. Hydrogen assisted cracking is not only controlled by local plasticity. Diffusion processes must also be involved. Hydrogen absorption, desorption, repartitioning of the hydrogen between traps, and plasticity interaction with grain boundaries might be the leading causes for the differences in crack propagation velocities for different embrittlement levels

Directeurs de thèse/ thesis director :

Döme TANGUY - Directeur de thèse

Loïc Vanel - Co-Directeur de thèse

Membres du jury / members of the jury:

Nom Prénom Etablissement de rattachement Membre

DIMANOV Alexandre Ecole Polytechnique Membre

GASPERINI Monique Université Paris 13 Membre

COLOMBANI Jean IUT Lyon 1 / Université Lyon 1 Membre

MOMPIOU Frédéric CEMES UPR 8011 Membre

TANGUY Anne INSA Lyon Membre

TANGUY Döme Université Lyon 1 Membre

VANEL Loïc Université Lyon 1

''