Synthesis and densification of materials |

|

The combination of high pressures, high temperatures and rapid kinetics allow the synthesis of solid compounds metastable remarkable properties. These treatments applied to nanomaterials are widening the new phases of field research and allow the development of nanostructured dense materials. |

People: Sylvie Le Floch |

||

|

|

|

|

|

||

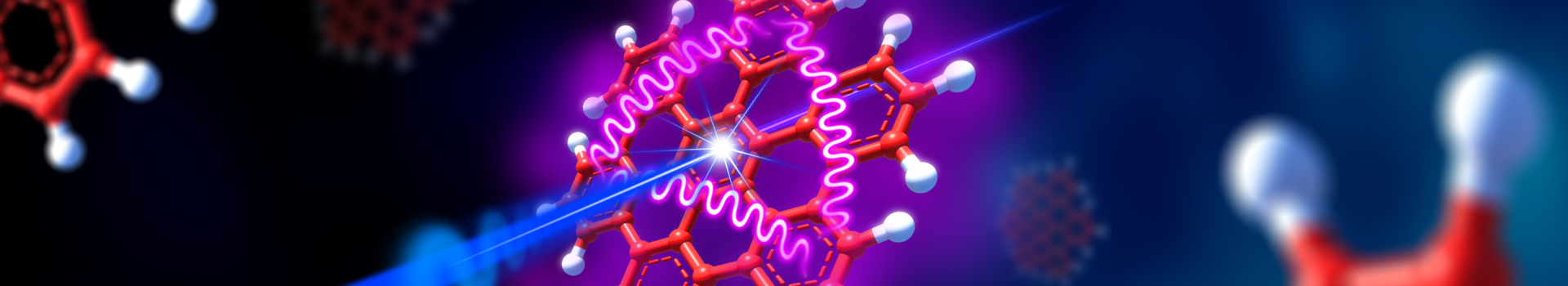

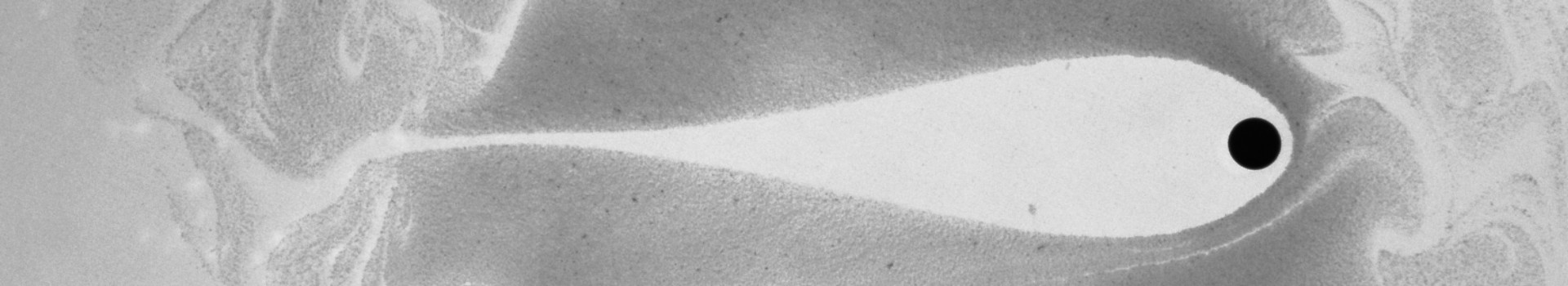

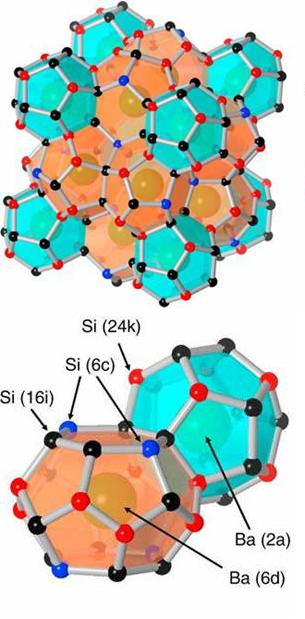

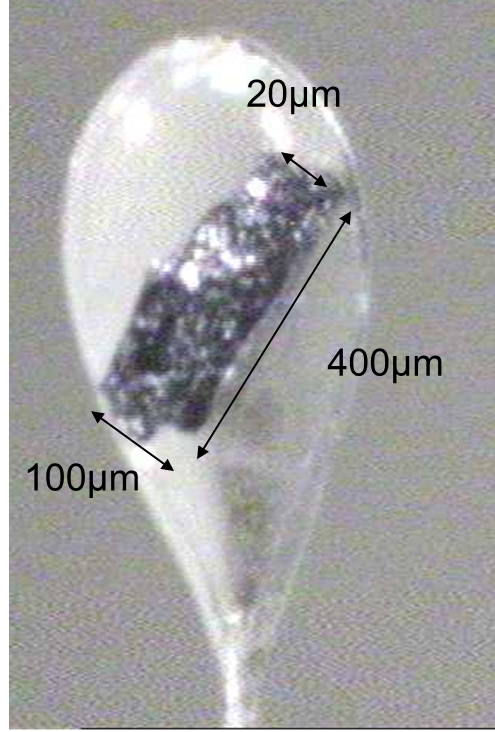

| Silicon clathrates Ba8Si46 synthesized 3GPa and 800 ° C. Artist view of the crystal (left), single crystal suspension (center); polycrystal process after HP-HT. |

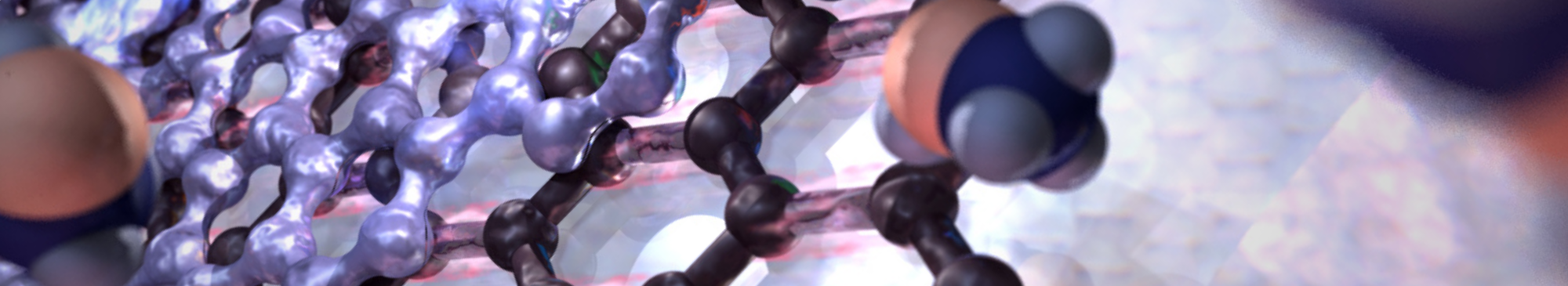

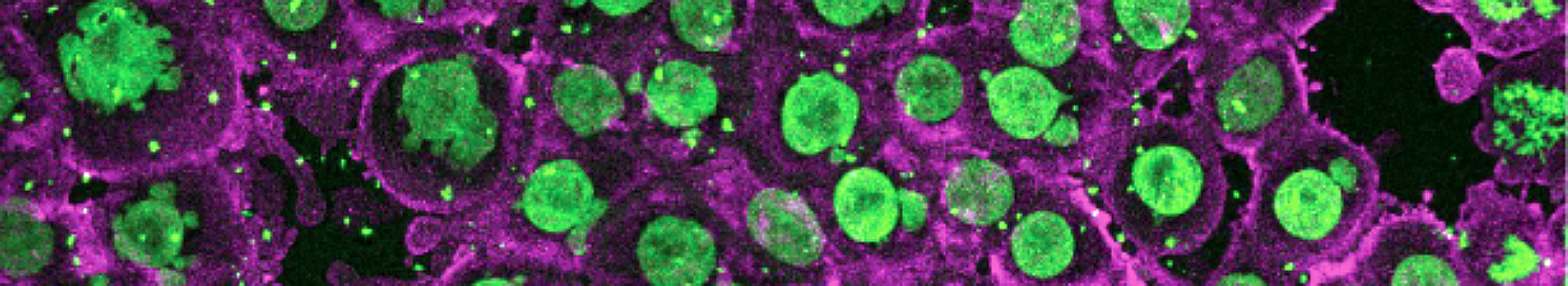

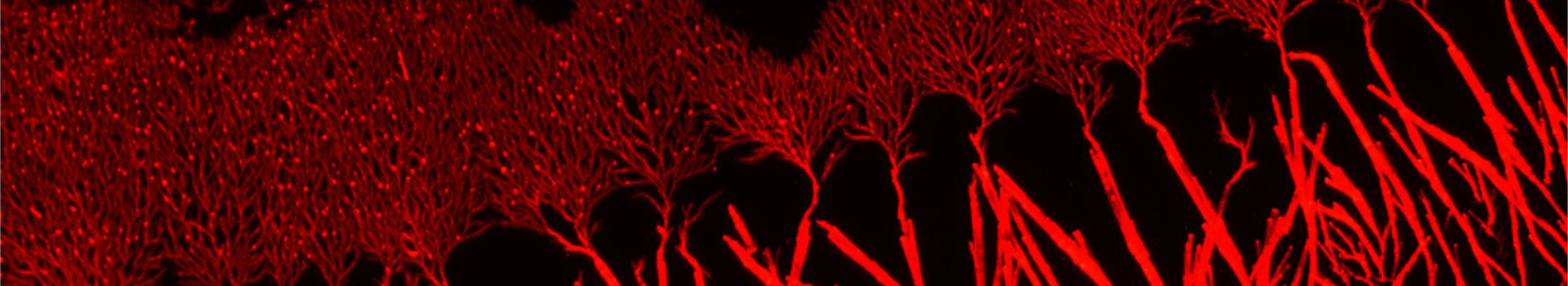

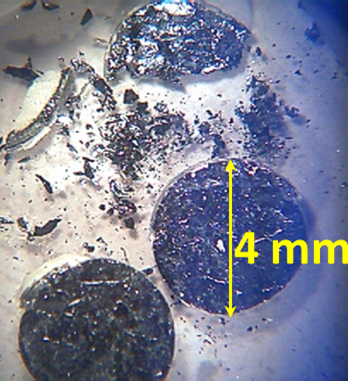

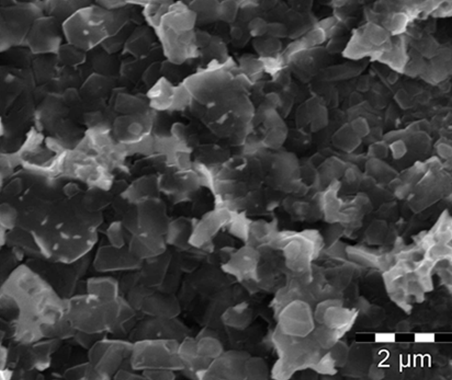

Diamonds synthesized from single walled carbon nanotubes at 15 GPa and 1400 ° C. |

||||

Synthesis at high pressure and / or temperatureThe high pressure devices called "large volumes" are used for solid phase reactions or phase transformations in extreme thermodynamic conditions for the densification of various materials. Crystal growth of high-pressure stages can be done by thermal gradient or hydrothermal synthesis in these devices.

|

||||

|

|

|

|||

|

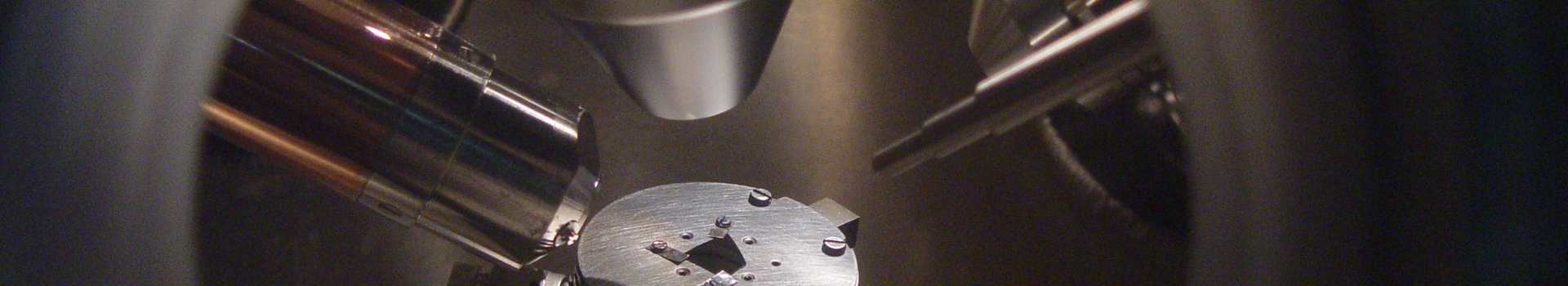

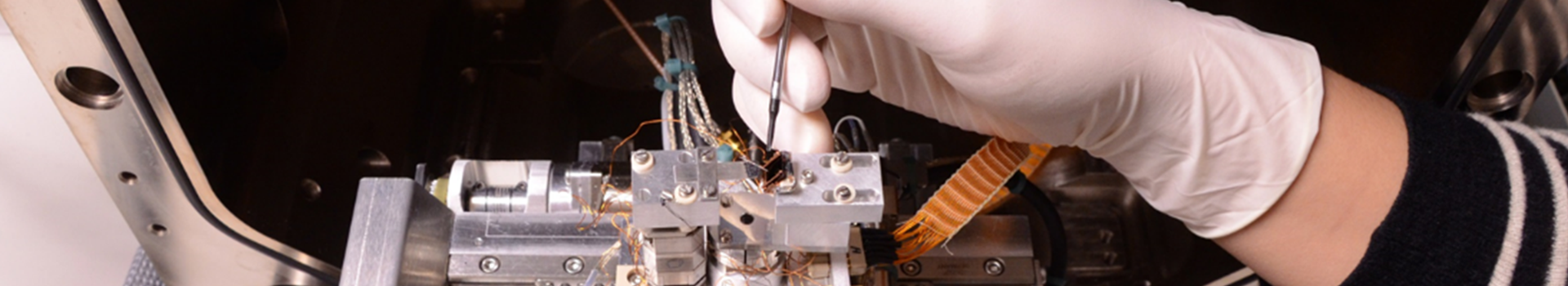

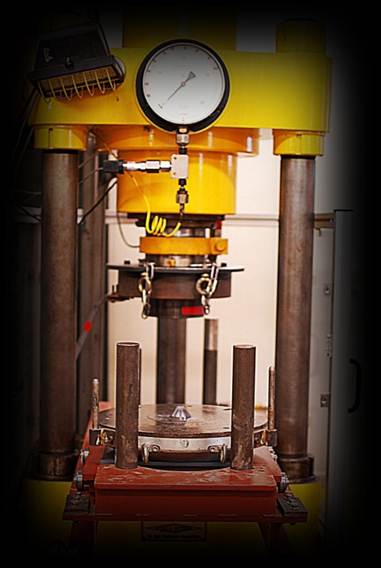

The Belt-type device achieves 5 GPa and 1500 ° C on a sample volume of 40 to 80 mm3. |

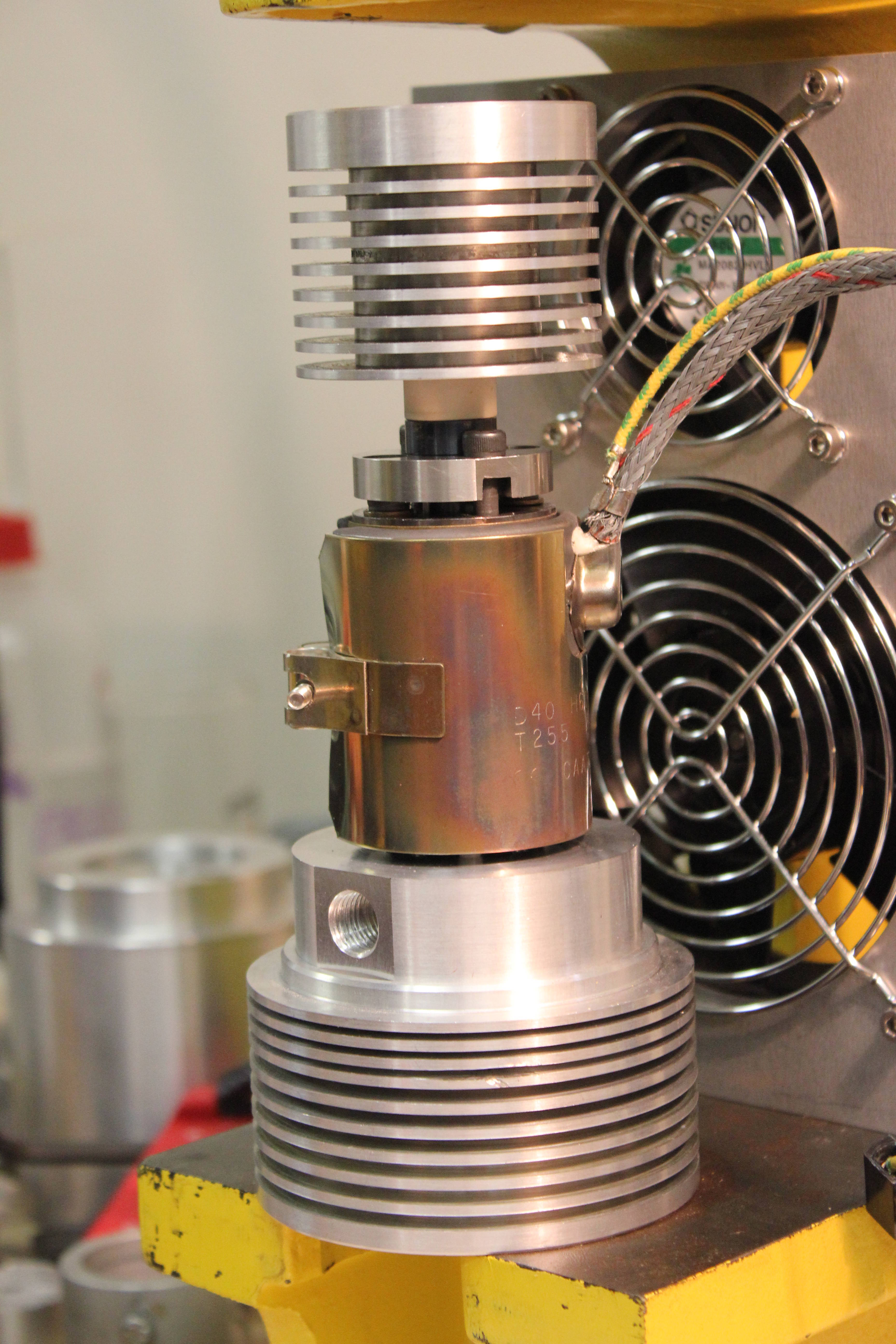

Paris-Edinburgh press achieves 15 GPa and 1500 ° C on a sample volume of 1 mm3. An adaptation for the densification of ceramics by spark plasma sintering at high pressure is under development (financing Mission Resources and Skills Technology CNRS). |

|||

|

|

|

|||

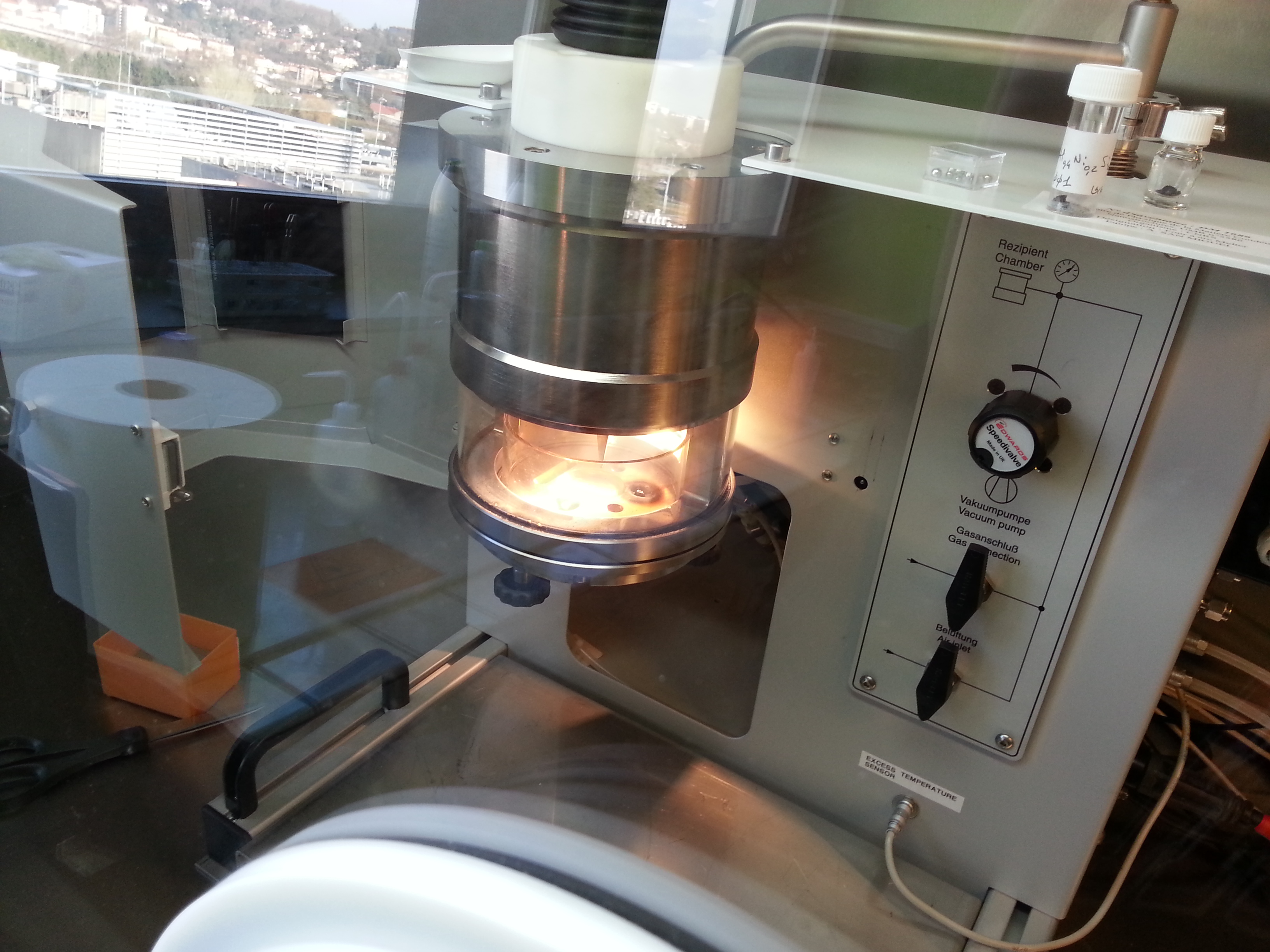

| Fusion arc (or arc melting) achieves very high temperatures (~ 3000 ° C) under contolled atmosphere (Ar). |

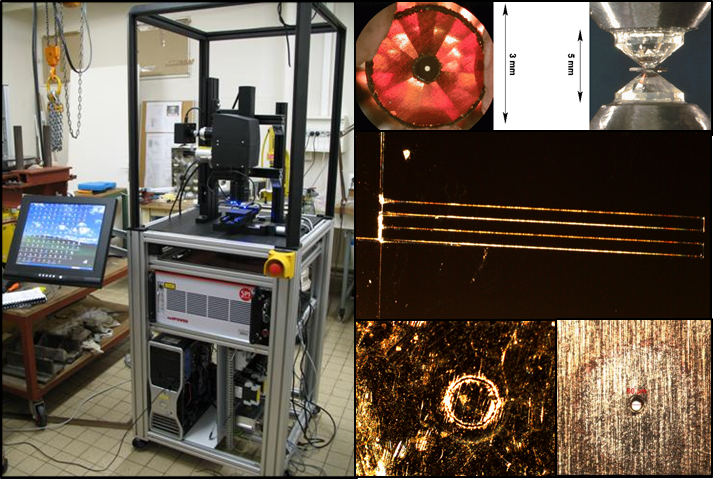

A cutting bench equipped with an SPI power laser operating in continuous or pulsed (25-100W) in the IR (1070nm) is used to produce cutouts of thin metals (e <100 microns), as well as microwelds with the XY stages (PI). (financing Mission Resources and Skills Technology CNRS). | |||

|

|

|||

| Pelletizer (600 MPa, 500 ° C) for large volumes. | Glove box with an optical microscope for loading diamond anvils cells and Paris-Edinburgh cells in anaerobic conditions and an arc furnace for the synthesis of intermetallic compounds. | |||

|

|

|||

|

Controlled atmosphere furnace for heat treatment under dynamic vacuum or gas flow (O2,Ar) or doping (eg alkaline) sealed tube under vacuum. |

||||

|

||||

| Ball milling (Spex 8000M) for crushing / mixing samples (from mass of 0.2 to 10g) up to speeds of about 1000 cycles / min. This allows to shape materials at nanometric scales and also to carry the mechano-synthesis. | ||||