Metallic nanoparticles have attracted a large and ever increasing interest in fundamental as well as applied research over the last years, revealing a rich and complex dependence of their physical and chemical properties as a function of size and geometry. Our experimental approach is based on the fabrication of well-defined benchmark systems, difficult to make but comparatively simple in the interpretation of their physical properties. Our physical fabrication technique allows the independent variation of one single parameter (cluster composition or size, environment etc.) in order to elucidate its influence on the nanostructure’s properties.

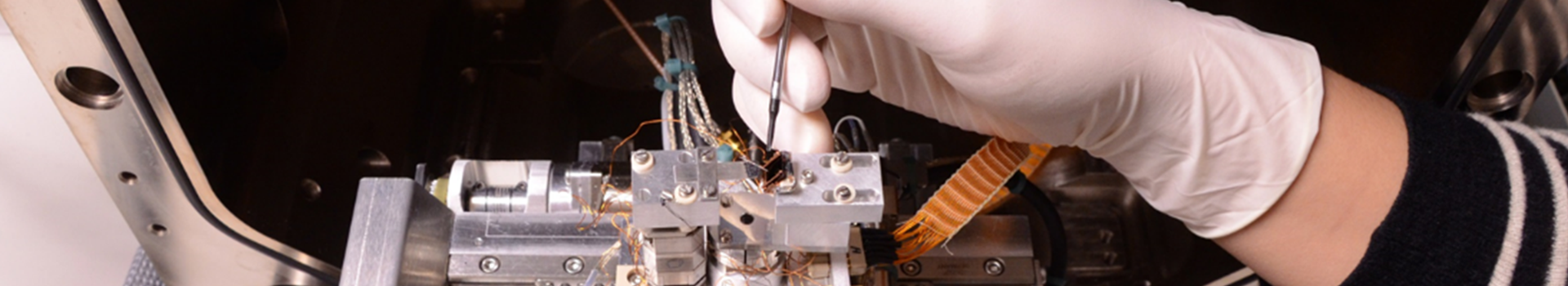

Metal clusters are fabricated in the gas phase and analyzed prior to their fragmentation-free deposition onto a substrate or embedding into a protective solid matrix (see fig. 1). Our sample fabrication method gives us full and independent control over the most important parameters: the chemical composition of clusters and matrix, the cluster size and their concentration. The different types of cluster sources and analytical tools are described in the experimental section.

Our scientific interest is mainly focussed on optical and magnetic properties of embedded metal clusters:

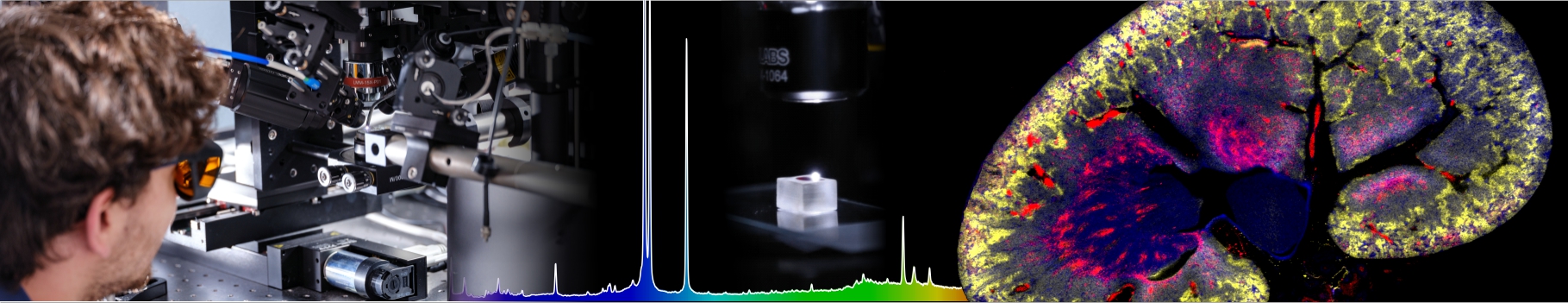

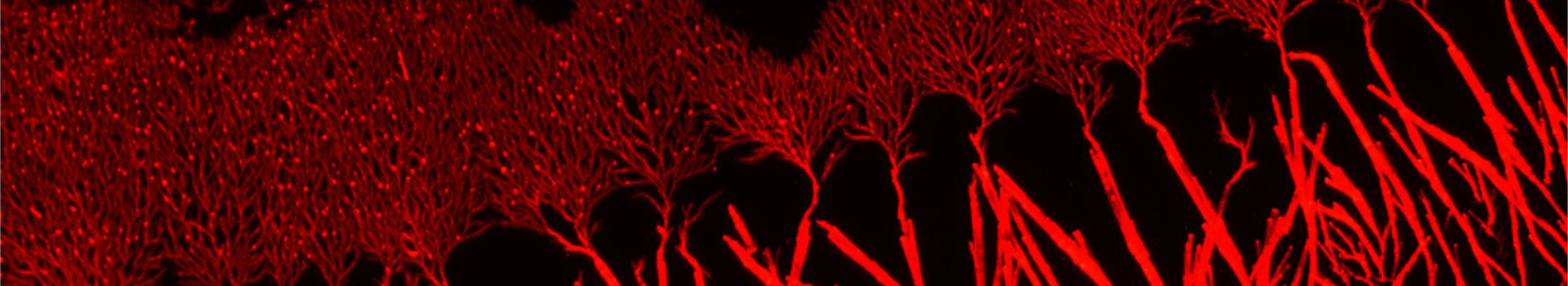

Mono or bimetallic metal clusters embedded in transparent oxide matrices are investigated with optical spectroscopy in order to infer their electronic structure and properties. This includes e.g. systems like Ag clusters of different size or mixed clusters such as CuxAg1-x or NixAg1-x in silica or alumina films. The surface plasmon is investigated by absorption spectroscopy whereas very small noble metal clusters are expected to also fluoresce. The close collaboration with the “FemtoNanoOptics” group of the ILM allows us to study dynamic effects with femtosecond pump-probe spectroscopy. Here the different relaxation dynamics and energy transfer processes are investigated time-resolved.

Magnetic clusters, typically cobalt, are embedded in non-magnetic matrices and studied with magnetic and magneto-transport methods in collaboration with the “Magnetic Nanostructures” group of the ILM. The scientific questions addressed comprise the size evolution of the magnetic properties and the detailed scattering processes in spin-dependent transport in granular nanostructures. The techniques used are SQUID magnetometry and spin-dependent transport in Giant Magnetoresistance and Hall Effect geometries.

Fig. 1: Schematic of the co-deposition technique.

Metal cluster fabrication

Our experimental approach to the study of nanostructured materials is based the extremely high quality of the samples to be investigated. This is achieved through the preparation of gas phase clusters prior to deposition onto a substrate. The subsequent experimental studies are either comparably straightforward or to be performed in collaboration with specialised scientists.

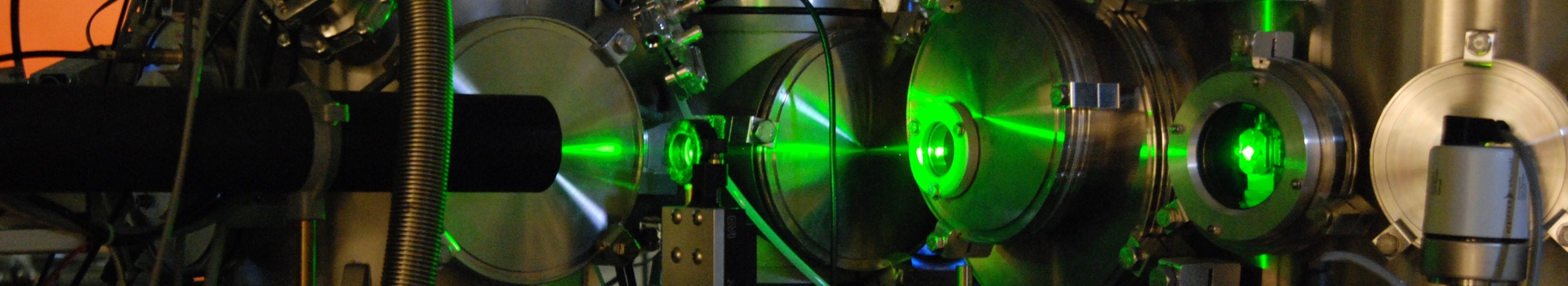

Laser vaporisation cluster sources

Three experimental setups based on laser vaporisation exist at the Lyon Cluster Platform (PLYRA). Metal clusters are produced in a laser vaporization-gas condensation source (see fig. 2). The plasma is created by the impact of a frequency-doubled Nd:YAG laser beam focused on a rod of the pure or alloy metal of chosen composition and thermalized by injection of a continuous flow of helium at low pressure inducing the cluster growth. Next, the clusters are cooled down in a supersonic expansion at the exit nozzle of the source. The obtained low-energy cluster beam is then co-deposited together with the atomic beam for the matrix. This co-deposition technique protects metal clusters from oxidation and allows us to independently adjust the cluster size and concentration.

Fig. 2: Laser vaporisation cluster source.

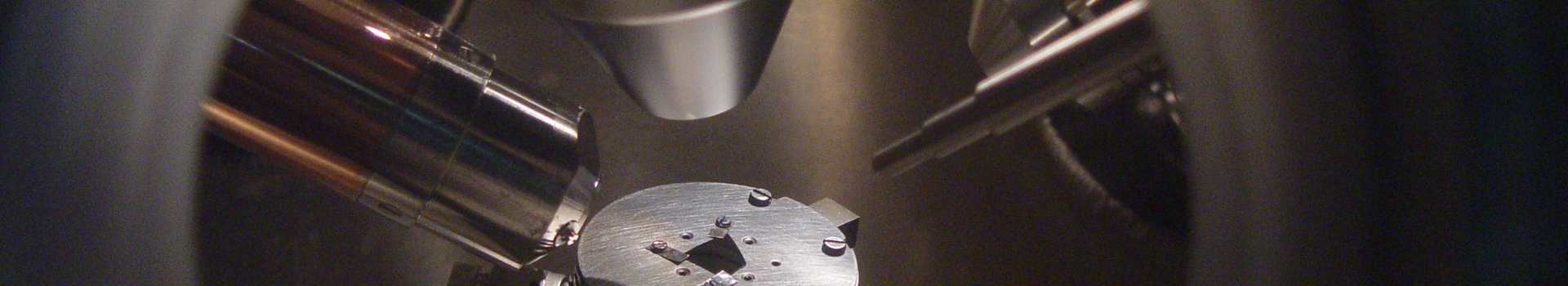

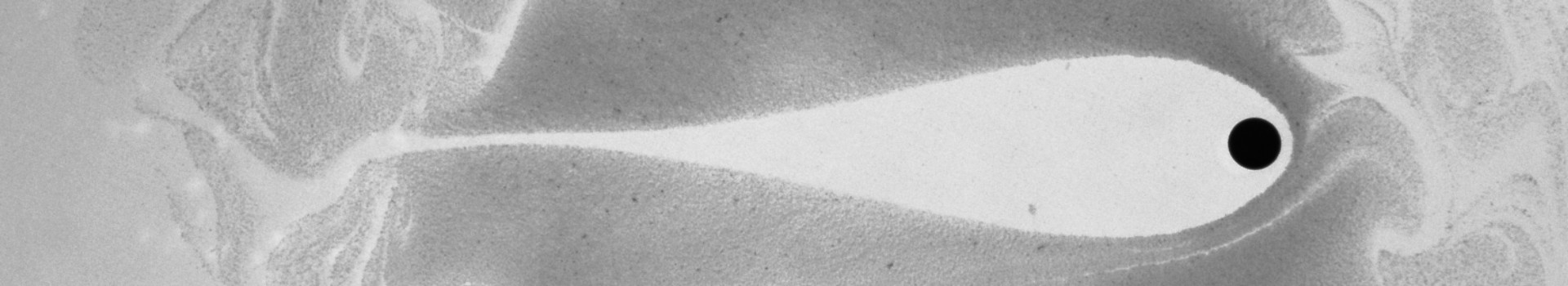

In two of the setups the whole cluster beam of ions and neutrals is directly deposited onto the substrate, in the third setup an electrostatic deviator is used as mass filter in order to reduce the relative size dispersion to <10% (see fig. 3). The generated cluster ions have almost the same velocity and can thus be separated with respect to their mass with the electrostatic energy filter. The cluster ion beam is characterized in the gas phase with a position-sensitive detector and a time-of-flight mass spectrometer. The mean cluster size obtained in this experiment can typically be tuned between 1.5 and 5 nm in diameter.

Fig. 3: Overview of the experiment for the deposition of size-selected metal clusters.

- R. Alayan et al. Application of a static quadrupole deviator to the deposition of size-selected cluster ions from a laser vaporization source. Rev. Sci. Instrum. 75, 2461 (2004) http://dx.doi.org/10.1063/1.1764607

Magnetron cluster source

This experimental setup is based on a home-built magnetron cluster source (see fig. 4) combined with gas phase cluster characterisation and possible mass-selection with a quadrupole. This setup allows producing intense currents of metal cluster ions in the gas phase over a wide range of sizes. The possibility to work with mass-selected clusters with an atomic precision is consequently included for masses up to 9000 amu (corresponding to ~80 Ag atoms). The machine is part of the Lyon Cluster Platform (PLYRA). It should be noted that this is the only setup worldwide of this type and performance.

Fig. 4: Overview of the magnetron cluster experiment.

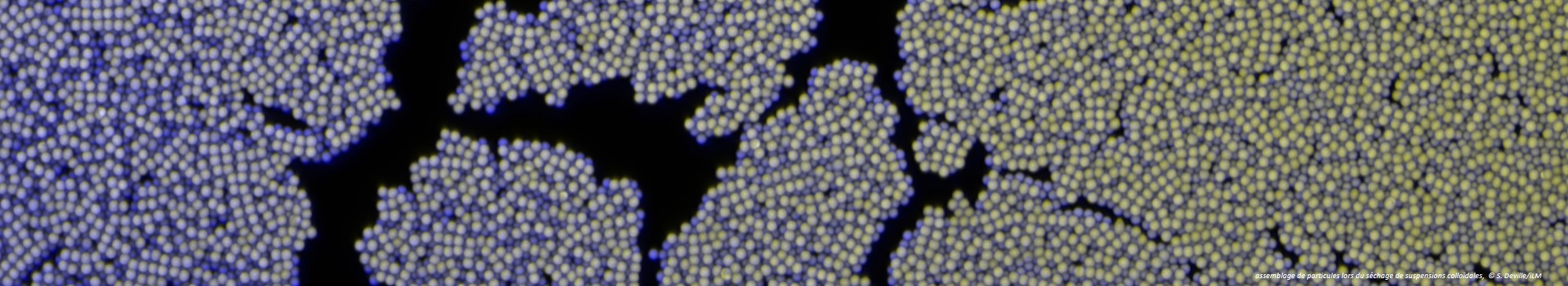

The magnetron cluster source generates intense ionised cluster beams over a wide range of sizes, from the atom to ~6 nm diameter (see fig. 5) and notably also in the range of 1-100 atoms/cluster, i.e. the range where quantum size effects of the electronic properties are expected. In this type of cluster source, metallic atoms are sputtered into the gas phase in a magnetron discharge. The metal vapour is quenched and transported towards the source tube exit by a carrier gas mixture of helium and argon in which the atoms aggregate. The variation of parameters such as gas throughput, discharge power and applied voltages permits the adjustment of the mean generated cluster size between atom and tens of thousands of atoms. A large fraction of the produced clusters is charged and consequently allows easy beam manipulation and characterisation.

Fig. 5: Typical cluster ion mass distributions as measured by time-of-flight mass spectrometry (TOF-MS), here for Co clusters.

The metal cluster ions are then guided through several differentially pumped vacuum chambers, mass-selected and deposited fragmentation-free onto a substrate, at the same time as the evaporated matrix. This technique thus gives independent control over all relevant parameters (chemical composition, cluster size and concentration) and the samples are stable at ambient conditions. They can be removed from vacuum to be investigated in different experimental setups, thus decoupling sample preparation and characterisation/study.

Typical nanostructured systems under study are e.g. Ag or Au clusters embedded in transparent oxide or fluoride matrices for spectroscopic studies or Co clusters in non-magnetic metals like Cu for magnetic and spintronic experiments.

- M. Hillenkamp et al. Monodispersed metal clusters in solid matrices: A new experimental setup, Rev. Sci. Instrum. 77, 25104 (2006) http://dx.doi.org/10.1063/1.2173051

Cluster-assembled nanostructures from preformed gas phase clusters

The systems studied consist of thin films (some 100nm) obtained by co-deposition of clusters generated by laser vaporization or magnetron sputtering and aggregation at the same time as the matrix. The protective matrix can, amongst others, be an oxide or a non-magnetic metal, depending on the scheduled experiments. The cluster concentration is adjusted to values that ensure absence of coalescence or inter-particle interactions. The mean cluster size can be adjusted by varying the source parameters. Size selection is achieved via kinetic energy filtering in order to obtain narrow size dispersions (~10%) in a size range between one and 6-7 nm in diameter [Perez, 2010]. The recently installed magnetron cluster source furthermore gives access to high cluster ion currents at sizes smaller than one nanometer.

Optical and vibrational properties

i. Bimetallic clusters

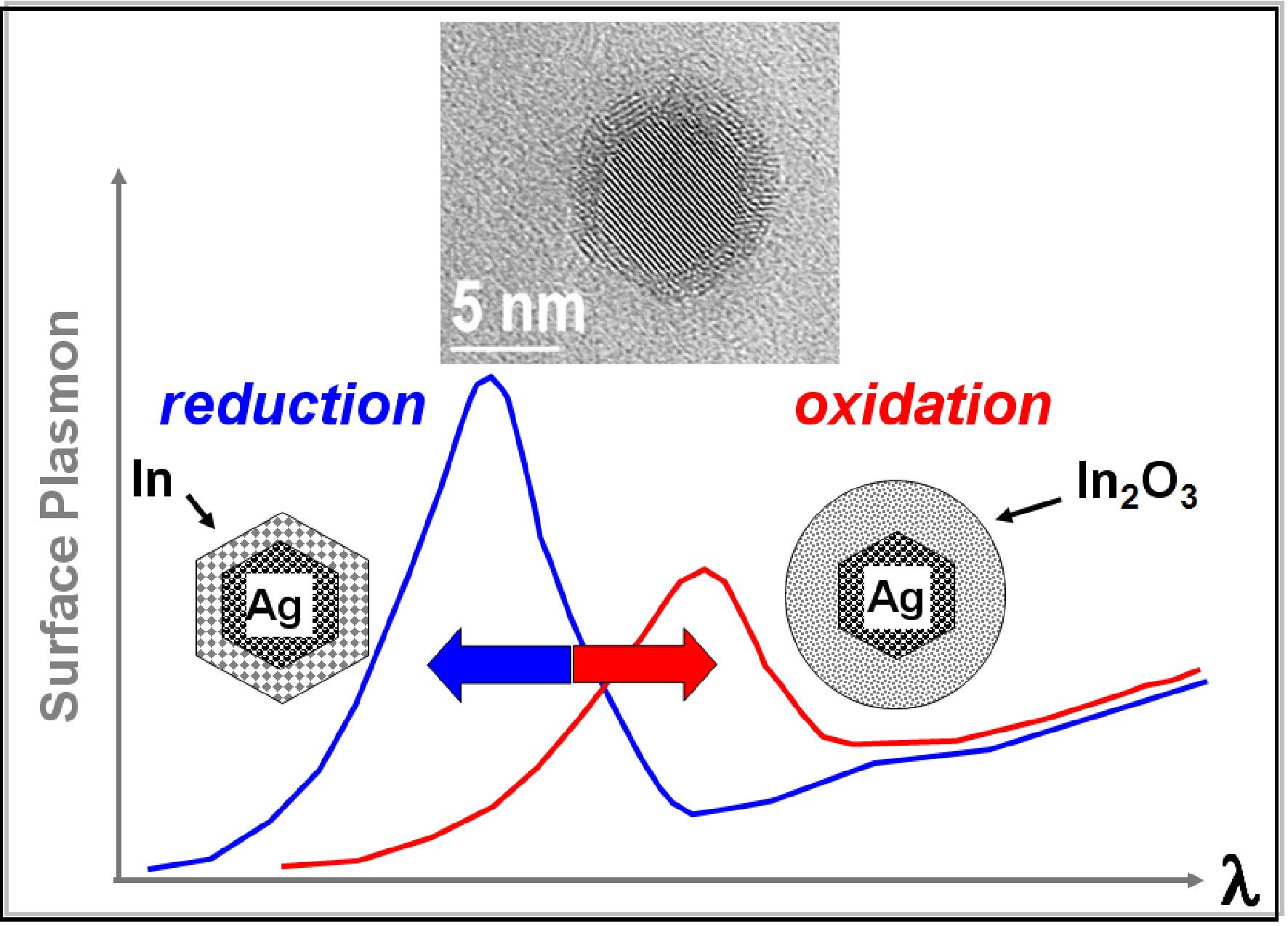

In the bulk phase bimetallic alloys have peculiar properties with respect to their constituents. By combining these with the characteristics specific to metallic nanoparticles, novel properties can emerge. Indeed the physical and chemical properties of nanoparticles strongly depend on the chemical order in the cluster (solid solution, segregated, core-shell). The advantage of our laser vaporization sources is the possibility to independently control the fabricated particle size and chemical composition. In continuity of our precedent studies performed on systems such as Ni/Ag, Au/Ag or Pt/Ag, we have studied bimetallic nanoparticles with a surface Plasmon resonance in the ultraviolet as well as systems with highly oxidation sensitive metals in order to fabricate nano-hybrid core-shell structures of a metal@oxid type. As an example the experimental study of In/Ag nanoparticles, a benchmark system for semi-quantal simulations, has shown a resonant absorption in the UV. This extension of plasmonics towards the ultraviolet in small clusters is promising for the development of plasmon enhanced sensors of attached biomolecules. The very high reactivity with oxygen of the indium shell on the other hand allows generating protected silver clusters encapsulated in In2O3. The purely metallic character of the nanoparticle can, however, fully be restored upon annealing in a reducing atmosphere (see fig. 6). The reversibility of this oxidation/reduction cycle is directly reflected the shift of the surface Plasmon resonance in the optical measurements and is in good agreement with electron microscopy and theoretical calculations [Cottancin, 2014].

Fig. 6 : Reversibility of oxidation/reduction cycle is directly reflected the shift of the surface Plasmon resonance

ii. Electronic relaxation dynamics

The nanostructured samples fabricated at the cluster research platform are used as benchmark systems of confined metals in the study of the relaxation after electronic excitation in collaboration with the FemtoNanoOptics group. We have studied, amongst others, the vibrational modes of small mass-selected platinum clusters. In time-resolved pump-probe experiments the initial excitation of the electron gas by the pump laser can initiate coherent vibrations of the cluster which induce a modulation of the dielectric function of the metal. This oscillation can then be probed via the differential transmission on a longer time scale (picoseconds). The small size dispersion of embedded metal clusters has permitted putting into evidence the fundamental vibrational mode (breathing mode) in small Pt clusters down to diameters of 1.3 nm, corresponding to less than 100 atoms. This phenomenon can, however, be surprisingly well described by a macroscopic model [Juvé 2010].

Nucleation - growth

The possibility to decrease the size dispersion had already permitted the comprehension of nucleation processes inside the laser vaporisation cluster source and shed light on the processes of nanostructuration and organisation of clusters soft-landed on surfaces. Further experiments in collaboration with L. Bardotti and F. Tournus of the “Magnetic Nanostructures” group of the ILM have shown that the cluster reactivity can significantly modify the morphology of nanostructured thin films and that the cluster size, their chemical composition (pure metals or alloys) and the chemical ordering (solid solution, segregated phase…) play an essential role. This has in particular been demonstrated for gold and platinum clusters as well as their alloys. Notably through the kinetic adsorption of species such as CO it is possible to avoid nearest neighbour contact on a substrate and to thus promote auto-organisation [Bardotti 2011a, 2011b, 2012].

Magnetism

These studies have been performed in collaboration with the “Magnetic Nanostructures” group of the ILM. The cluster size variability and monodispersity of samples fabricated with the magnetron cluster source together with the development of advanced data treatment methods [Hillion 2012] has permitted studying quantitatively size effects in the magnetic anisotropy of embedded cobalt clusters and understanding their microscopic origins (shape vs. surface anisotropy, determinant for diameters above and below ~3 nm, respectively) [Tamion 2009, Tamion 2010, Tournus 2010, Tournus 2012]. Moreover the influences of alloying, of inter-particle interactions [Hillion 2011] and of the nanoparticle/matrix interface [Tamion, 2011] on the magnetic properties have been studied. Finally the biodegradability of iron-oxide nanoparticles used as contrast agents and in theranostics has been investigated in the metabolism of mice.