Thèses

Vendredi 23 Septembre 2022 à 10h00.

Glass processing with ultra for laser pulses

David SOHR

(david.sohr@univ-lyon1.fr)

Salle de conférences BU Sciences-La Doua

Invité(e) par

Stefan SKUPIN

présentera en 2 heures :

''

Membres du jury / jury members :

Eric CONSTANT

Francois COURVOISIER

Stefanie KROKER

Vincent MORRO-ROS

Stefan NOLTE

Rachel NUTER

Stefan SKUPIN

Jens Ulrich THOMAS

Résumé / Abstract :

Set in the wide and continuously growing field of glass processing with ultra short laser pulses, this

work deals with the cutting and edge shaping of glass sheets. Laser beams with elongated focal

geometries have previously been used to perforate even thick glass sheets with single laser shots and

thus enabled fast and clean cutting processes. These line foci so far have been limited to straight

geometries resulting in sharp edges, which for many applications require an extra processing step

to obtain a c-cut edge. The c-shaped Airy beam on the other hand has been employed in ablative

processes to create curved edges and trenches in thin sheets of silicon and diamond. This work

describes the application of the Airy beam to the micro perforation cutting process in glass.

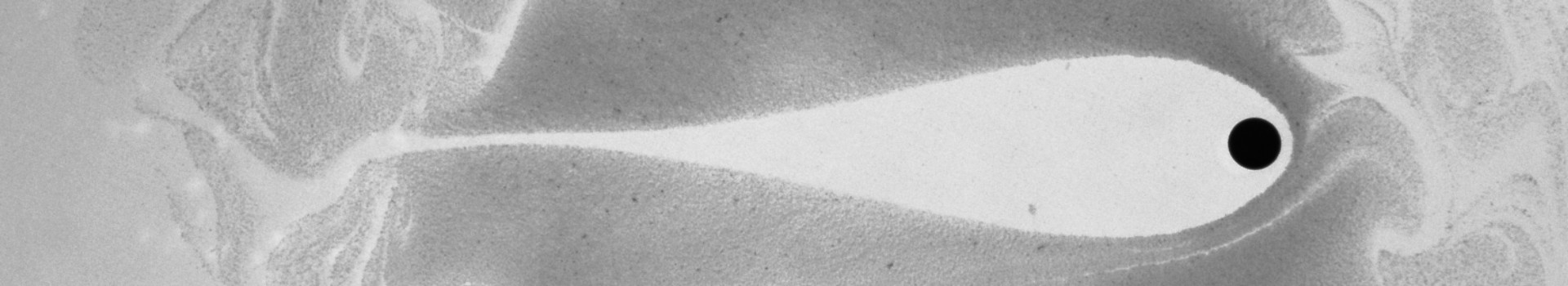

For this, the linear propagation of the Airy beam focus is reviewed with respect to the achiev-

able length, curvature and focal contrast that depend on the focusing conditions. With an effective

numerical aperture of 0.13 volume modifications of up to more than 2 mm length are demonstrated

in borosilicate glass, that follow very well the expected parabolic trajectory of the Airy beam with a

bending radius of 12 mm. Applying the Airy modifications for micro perforation for the first time,

glass sheets with rounded edges have been achieved after etching with a bending radius down to

727 μm in a 600 μm thick sheet.

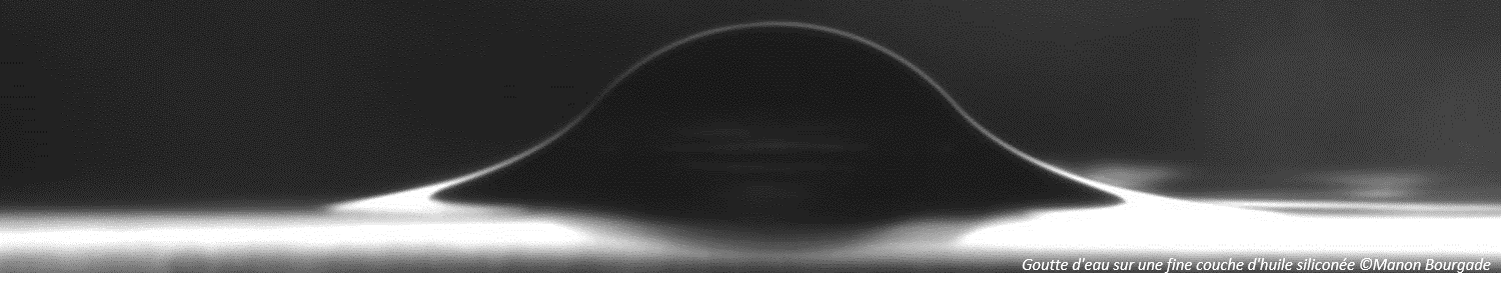

The most crucial limitation of the Airy beam with respect to the micro perforation process is the

relatively low focal contrast that leads to absorption and material damage in the side lobes of the

beam. This can be observed experimentally as an effective tilt of the Airy beam due to the pref-

erential absorption in the upper part of the glass modification and is corroborated by non linear

simulation results. Adjustments of the optical setup allow the compensation of this tilt and lead to

the production of a symmetric edge.

The influence of the damage in the side lobes proves particularly problematic for separation by

mechanical cleaving. Further adjustments of the Airy beam can be used to align the cracks that are

caused by the laser perforation process along the intended cutting direction, i.e. orthogonal to the

plane of maximum curvature. Going further, the Airy beam is a promising candidate for light sheet

cutting, which will enable even faster micro perforation cutting processes by replacing the focal line

with a focal surface. In this work, the first sheet like in-volume modification induced by a single laser

shot is demonstrated.

''