More highlights |

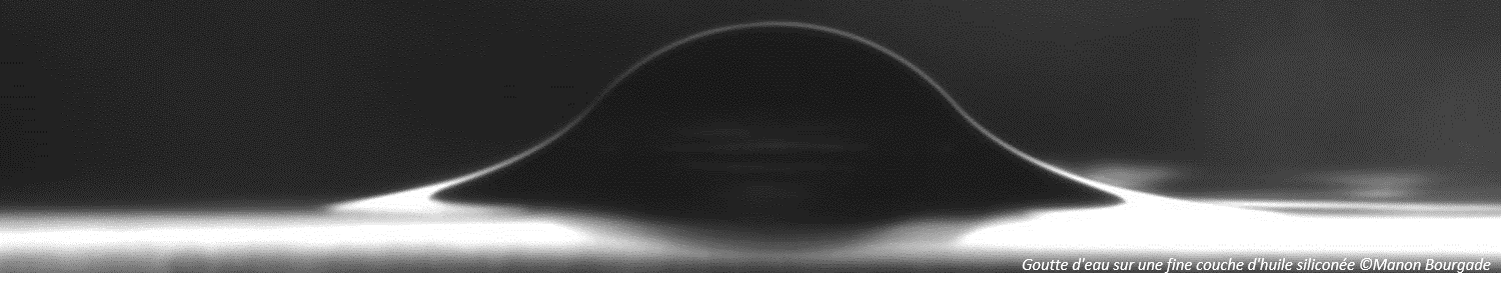

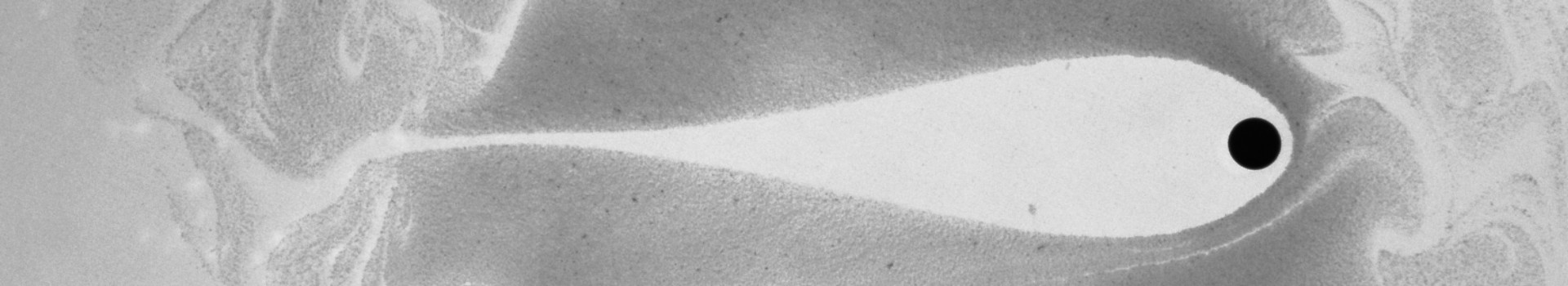

Capillarity of yield stress fluidsWe use yield stress fluids like microgels to perform different kinds of capillarity experiments : capillary rise, bridge tensiometry, wetting... These situations provide an original way to probe the interplay between equilibrium properties like surface tension and dynamical arrest due to the fluid solid-like behavior. Capillary rise of yield-stress fluids, Géraud et al., Europhys. Letters (2014). Yield stress and elasticity influence on surface tension measurements, Jørgensen et al., Soft Matter (2015). |

Capillary bridge of carbopol gel and capillary rise of several fluids. |

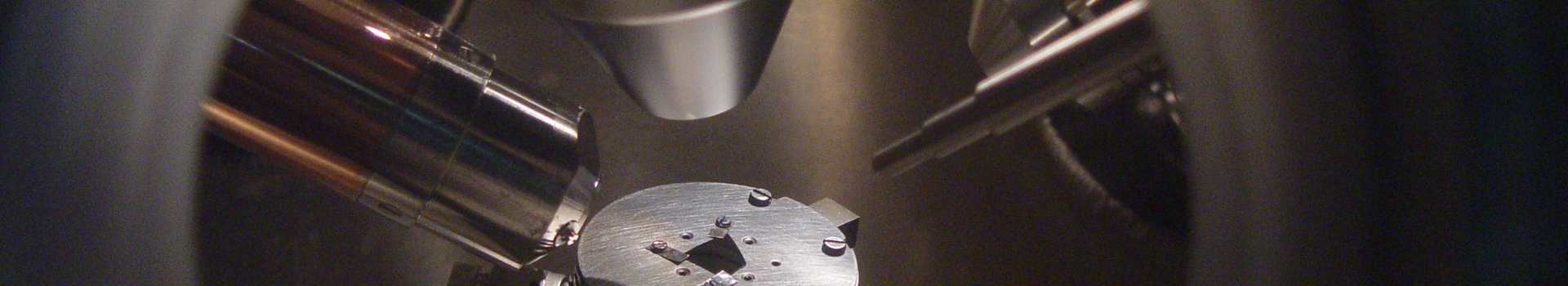

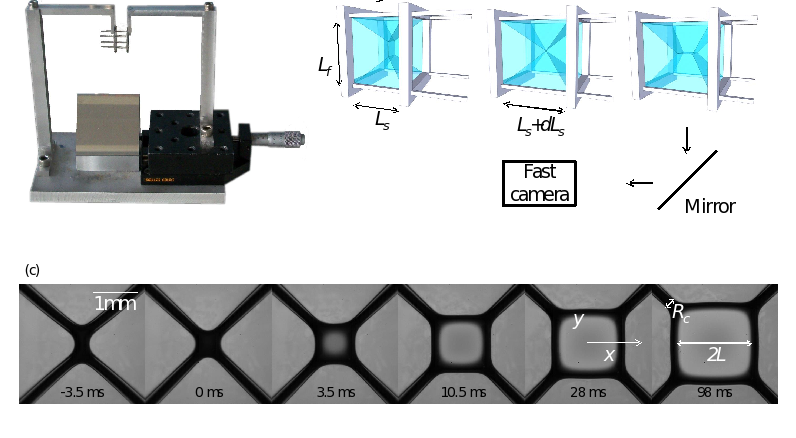

Topological rearrangement in a soap film assemblyA specific soap film architecture has been designed to study the structure of the freshly formed film during a topological rearrangement. PIV, interferometric and absorption measurements allow to define two distinct mechanisms of soap film generation depending on the physicochemistry of the soap film solution. These results have large impat on the understanding of foam rheology. On the generation of a soap film during a topological rearrangement, Petit et al., Journal of Fluid Mechanics (2015) |

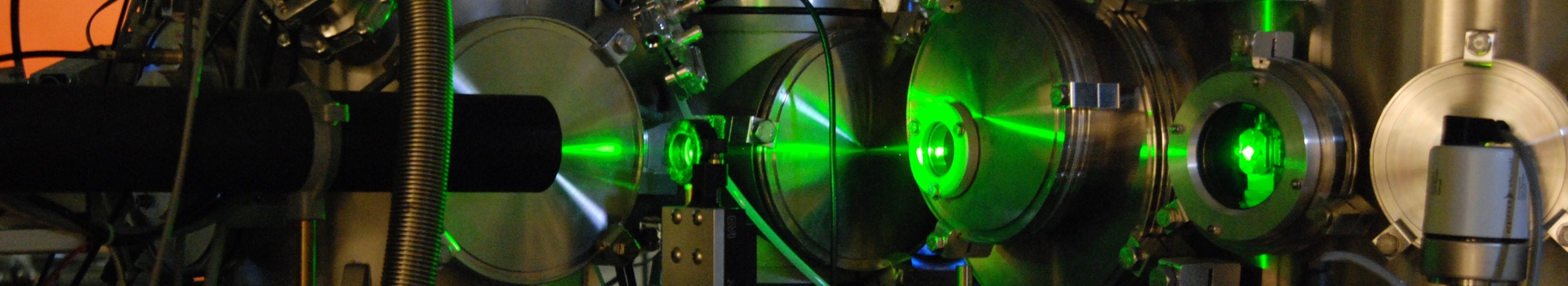

Set up used to mimick a topological rearrangement in a liquid foam. |

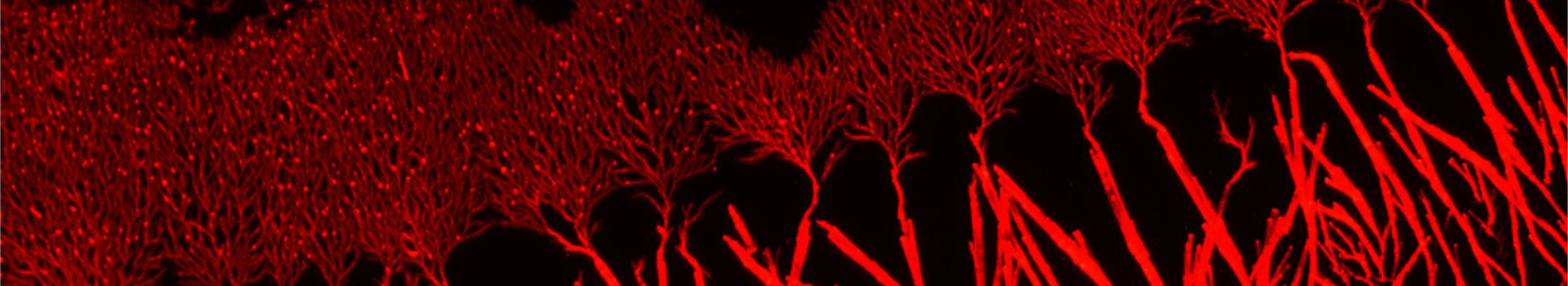

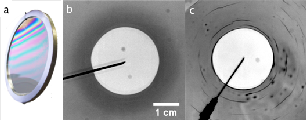

"Cracks" in rigid soap filmsWe study the influence of the physico-chemistry of surfactants on soap film bursting dynamics, in order to understand its effect on liquid foam stability. With certain type of surfactants, the bursting dynamics deviates from the classical established law, providing a new method to measure the interfacial elasticity of the surfactant solutions. Besides, new "crack" patterns, similar to fractures in a solid membrane, are observed during the liquid film opening. Holes and cracks in rigid soap films, Petit et al., JFM Rapids (2015). |

(a) Soap film withdrawn from a liquid bath. (b) Opening hole in a film of colored soap. A darker i.e. thicker aureole is visible around the hole.(c) Bursting of a rigid soap film with visible « cracks ». |

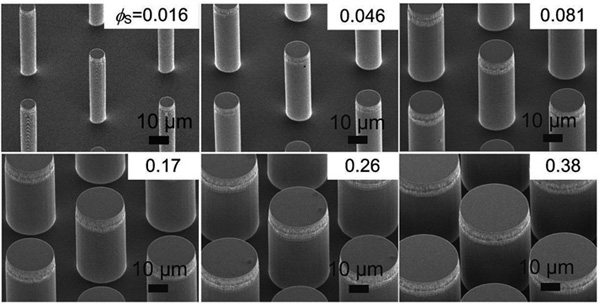

New Cassie-Wenzel dynamic transition upon drop impactYet another special dynamical behavior with Super-hydrophobic surfaces. Thanks to the nice textured surfaces developed by Choongyeop, we have identified a new regime during drop impact. This regime corresponds to a Cassie-Wentzel transition occurring during drop recoil. it is distinct from the water hammer mechanism, or from the pancake bouncing recently reported in the literature. Two types of Cassie-to-Wenzel wetting transitions..., Lee et al., Soft Matter (2015). |

Micro-textured pillar surfaces with varying solid fractions. |

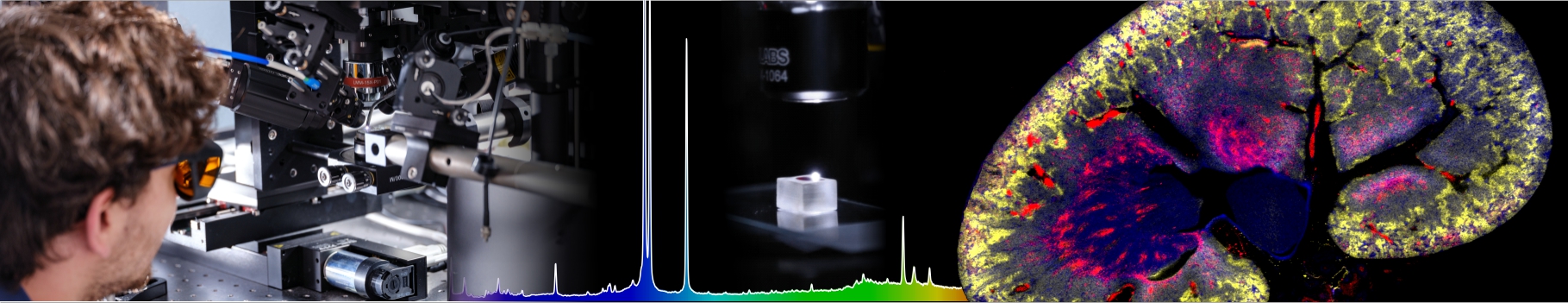

Drop impactsWe study the dynamics of drops impacting a solid surface. Using experimental tools that provide the local thickness and velocity of the liquid lamella, we compare impacts at room temperature with impact on a hot surface, where calefaction makes the liquid-substrate fraction negligible. Our approach allow us to evidence a viscous layer in the former case, and a purely convective flow in the latter. Bridging local to global dynamics of drop impact onto solid substrates, Lastakowski et al., Journal of Fluid Mechanics (2014) |

Impact of an ethanol drop on silicon wafer. (a) calefaction on a substrate maintained at 350°C, (b) on a cold substrate. |

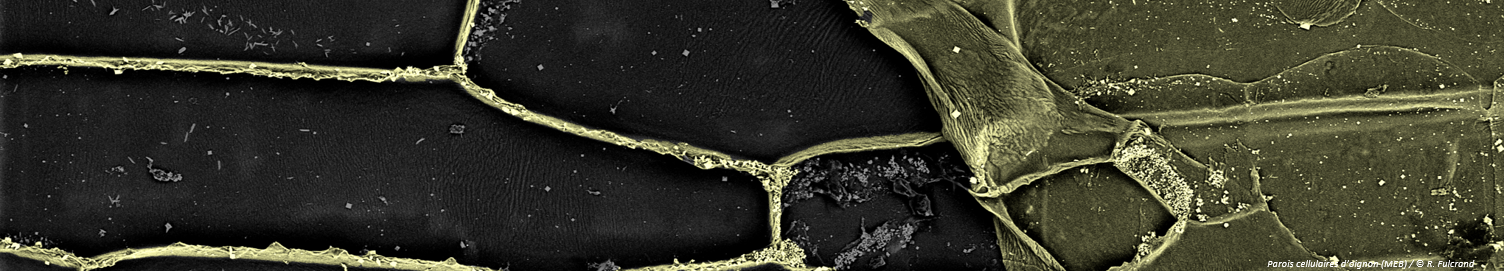

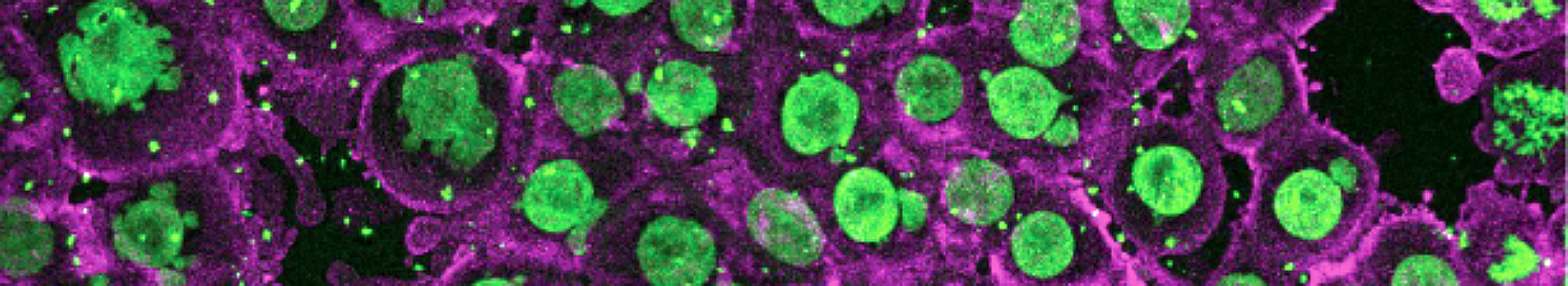

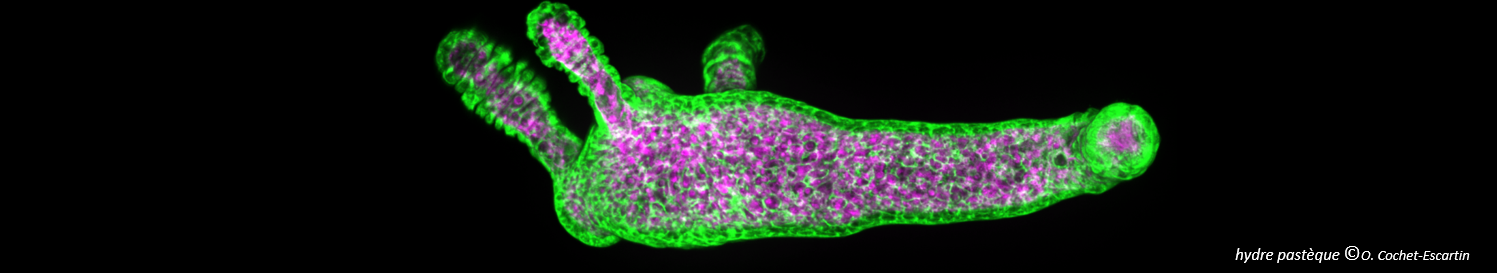

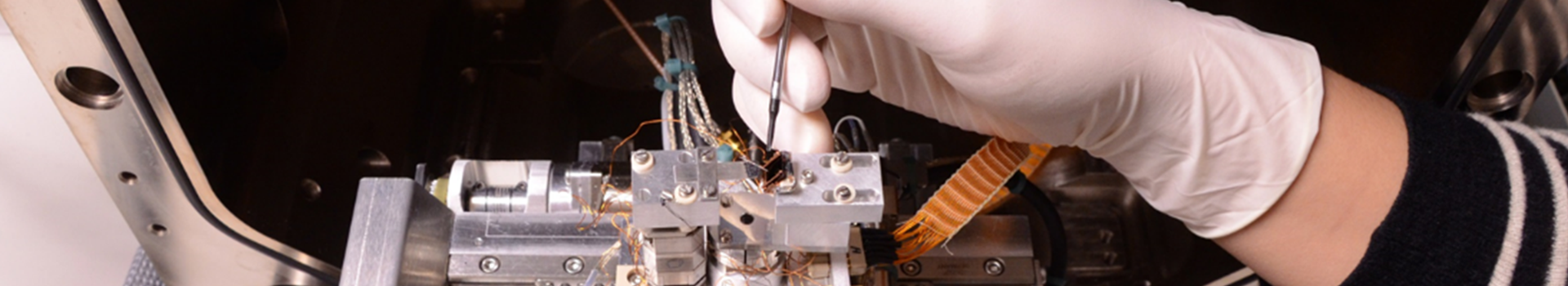

Shearing of cellular aggregatesTo understand cellular motility and morphogenetic processes, we study mechanical properties of aggregates made of hundred of cells. Using a blade tensiometer, we have found an elasto-plastic behavior at short times (<10 min) and a viscous behavior at long times (hours). The properties at short times are also probed by a rheometer. A model based on the soft glass rheology allow to rationalize the main results observed with the rheometer. Multicellular aggregates: a model system for tissue rheology, Stirbat et al, EPJE (2013). |

A) Aggregate compressed between two walls. B) Two-photon microscopy image of a type F9 WT aggregate C) Hundreds of aggregates sheared in the rheometer. |

|

Elementary processes in foamsWhenever a foam flows, drains or break, the bubbles making the foam move with respect to one another. Using experiments on model film assemblies, we investigate the structure and dynamics of such rearrangements. In particular, we seek to understand the role played by the surfactant. Moreover, we try to connect the rearrangement phenomena with macroscopic properties of the foam such as stability and rheology. How topological rearrangements and liquid fraction control liquid foam stability, Biance et al., Phys. Rev. Lett. (2011). |

(Left) Soap film geometry that allow a topological rearrangement and observation of the newly created film. (Right) Interference pattern on a newly formed film of width 1 mm. |

|