Complex fluids

Members

- Nicolas Bain

- Catherine Barentin

- Anne-Laure Biance

- Marie Le Merrer

- Mathieu Leocmach

We seek to understand dynamical processes that govern stability and flow of complex fluids, which include amorphous systems, foams, disordered materials, yield stress fluids, etc. The goals that underline many of our experiments is to explain the macroscopic response of these materials from the microscopic structures and dynamics, and to understand the role of surfaces and confinement.

Highlights

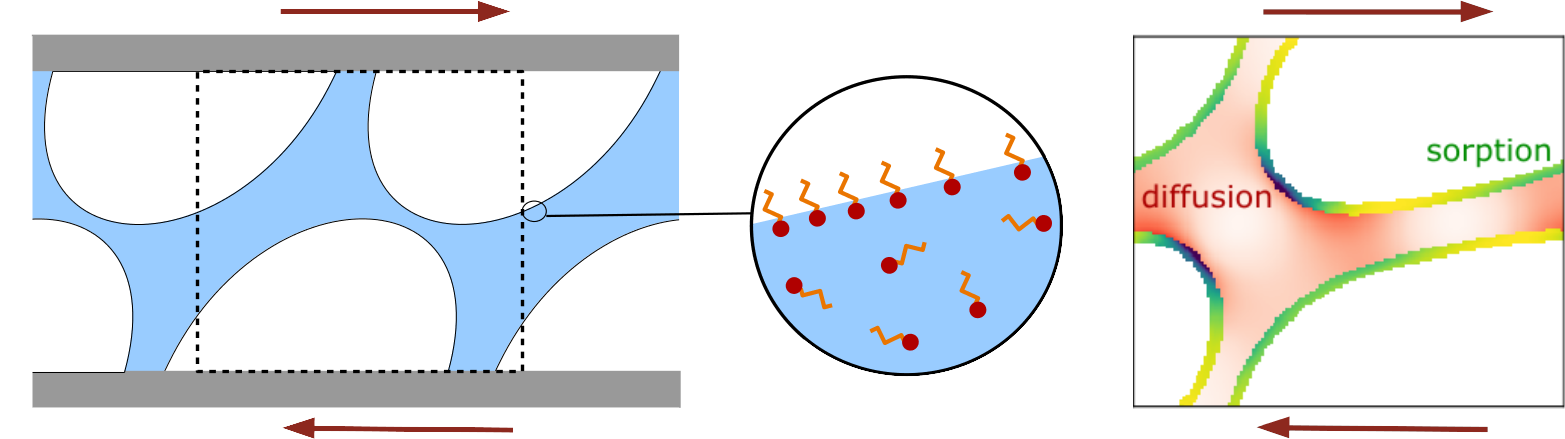

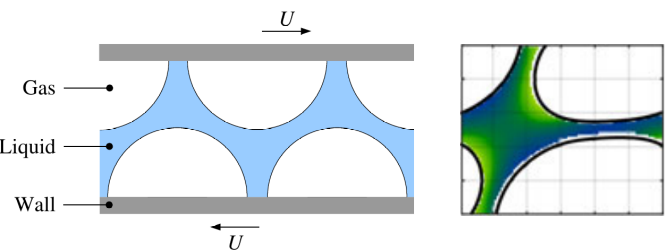

Energy dissipation in a flowing foam

The way a foam flows is dependent on the surfactant used. Why? We use numerical simulations of an elementary bubble rearrangement to resolve at the bubble scale the surfactant distribution and dynamics. We rationalize the results by extending the classical Lucassen model from a thermodynamic perspective. Our framework reveals the origin of surfactant-induced dissipation in sheared foams and is applicable to other surfactant-controlled systems.

Surfactant-induced dissipation in sheared foams: Mechanics and thermodynamics, Y. Mezache, et al., Phys. Rev. Fluids (2024).

Linking cheese microstructure and its mechanical response

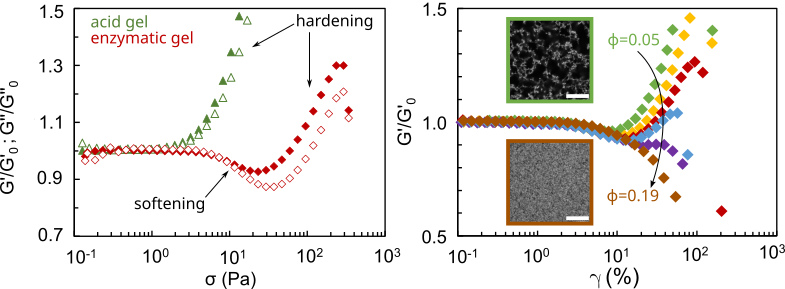

Enzymatic casein gels are fundamental to the cheese industry. In particular, the nonlinear mechanical response of these gels had been little studied, even though it plays a crucial role in several key stages of cheese production. We were able to demonstrate that this response differs from that of casein gels formed by acidification (yogurt). In particular, enzymatic gels soften at intermediate deformations before hardening at large deformations. While hardening is common to all gels with a fractal network, softening is rarer. Thanks to control experiments made possible by collaborations with food science specialists at INRAE, we were able to show that the softening did not come from the structure of the network, but its constituents, i.e., the casein micelle. The structure of the "micelle" is preserved by the action of enzymes but lost during acidification. The difference in mechanical behavior at the macroscopic scale is thus determined at the scale of a few tens of nanometers.

Thanks to this study, we were able to show a remarkable influence of a microscopic scale on the macroscopic scale, while the microstructure at intermediate scales is preserved. This result shows the importance of a multiscale approach for understanding the microstructure-property relationship in disordered systems.

Non-Linear Properties and Yielding of Enzymatic Milk Gels, Bauland et al., Soft Matter (2023).

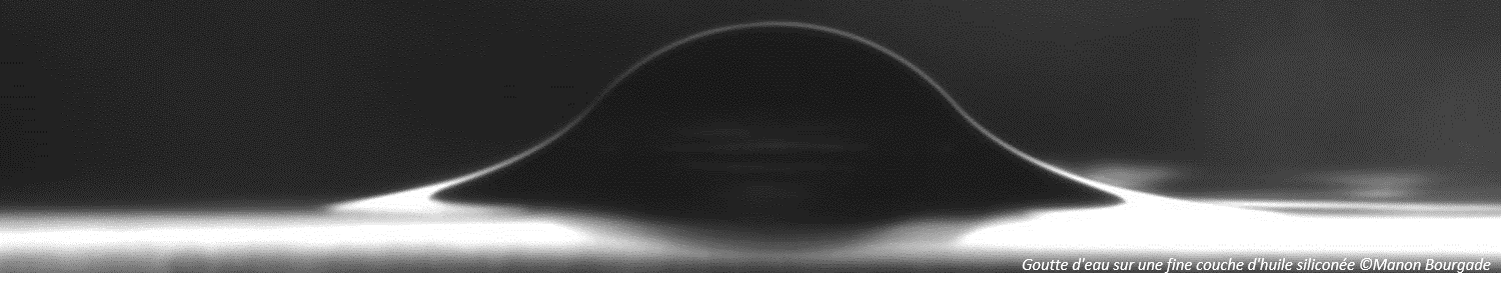

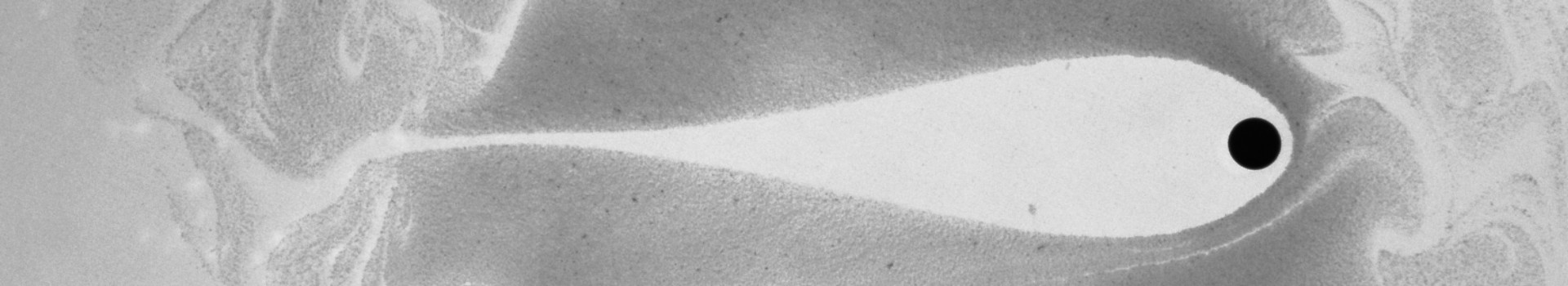

Spreading of drops made of yield-stress fluids

Contrary to what is observed with Newtonian fluid and stated by the Young’s law, the final contact angle reached during the spreading of a drop made of yield stress fluids depends on the drop size, on the fluid rheology and on the hydrodynamic boundary conditions. These results can be rationalized in terms of dynamic arrest due to the existence of a yield stress.

Dynamic arrest during the spreading of a yield stress fluid drop, Martouzet et al., Phys. Rev. Fluids (2021).

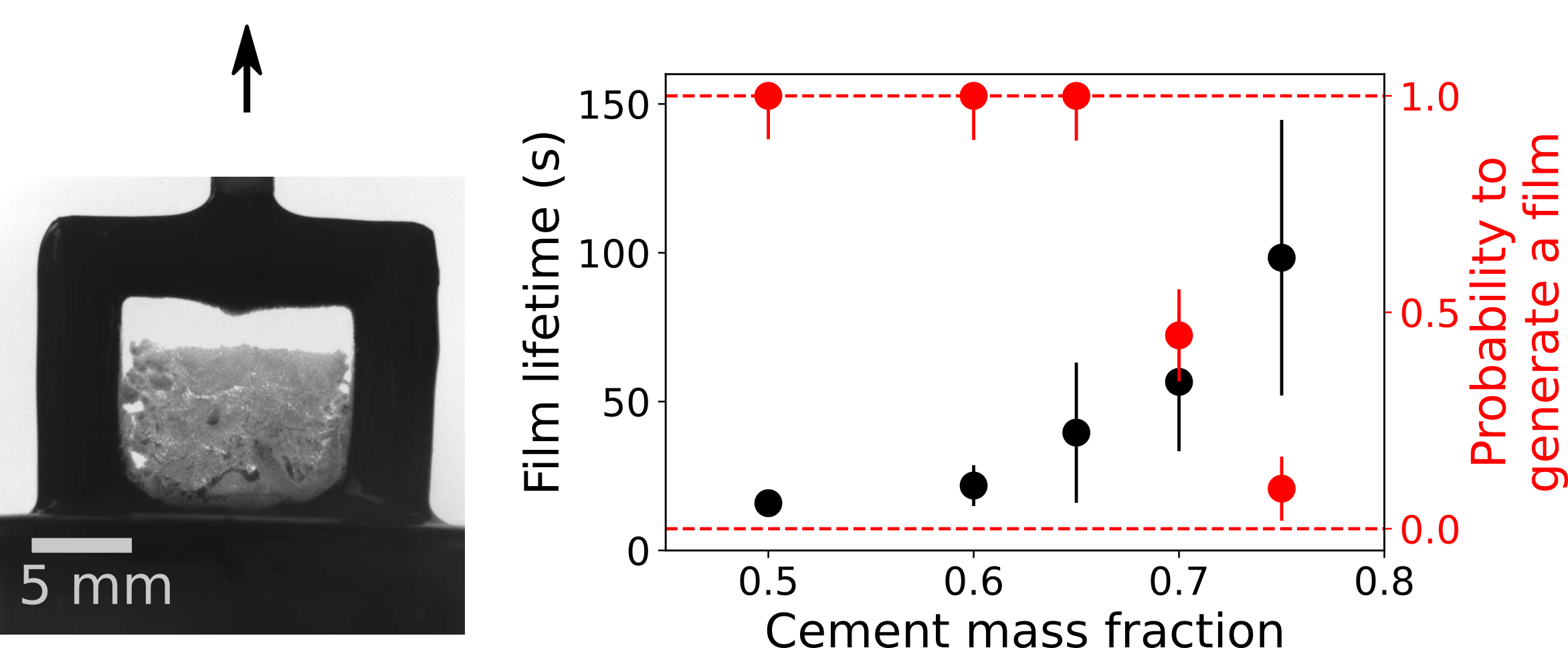

Generation and stability of cement soap films

By withdrawing a frame from a fresh cement suspension at controlled velocity, we find an optimum solid fraction to achieve both generation and stability of the cement soap films. These films are the elementary units of foamed cement used to elaborate new porous insulating building materials.

Generation and stability of cement soap films, Ahmed Abdourahman et al., Soft Matter (2021).

How ions control the rheology of calcite gels

Simple ions like calcium or sodium adsorb on mineral surfaces and control interparticle forces between colloids of calcite (calcium carbonate) found in industrial and geological processes. Solution physicochemistry thus provides a control on the elasticity of calcite gels and on flow properties like shear banding.

Simple ions control the elasticity of calcite gels via interparticle forces, Liberto et al., J. Colloid Interface Sci. (2019). Interparticle attraction controls flow heterogeneity in calcite gels, Liberto et al., Soft Matter (2020).

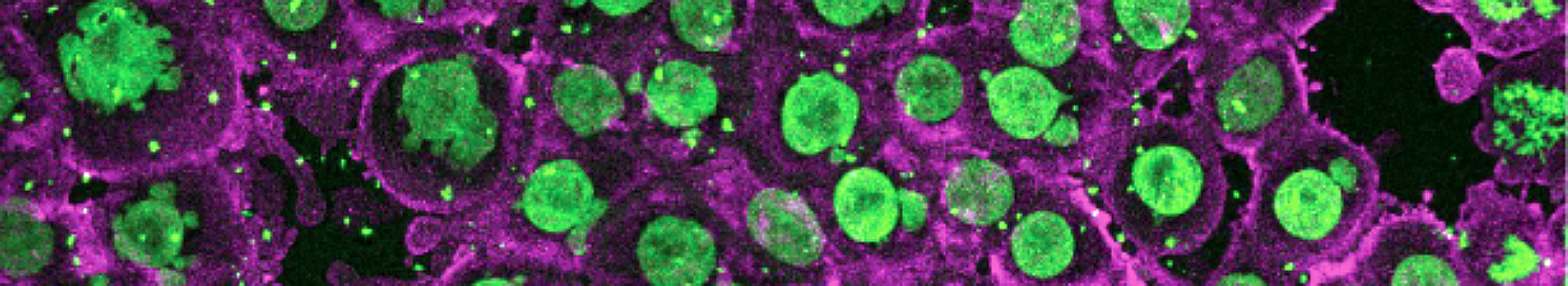

Wall slip of polymer microgels flows

We use microfluidics channels to measure the slip velocity of jammed suspensions of polymer microgels as the wall stress is increased by 4 orders of magnitude. The friction law exhibits a transition in slip regimes, from a nonlinear to a linear scaling, linked to two distinct dissipation mechanisms at the scale of the soft elements, determined independently through fluorescent microscopy.

Wall slip regimes in jammed suspensions of soft microgels, Péméja et al., Phys. Rev. Fluids (2019)

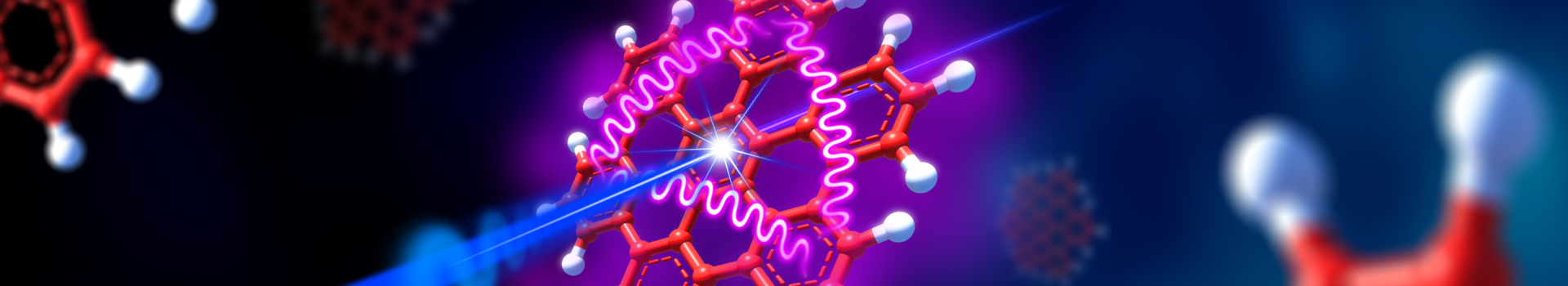

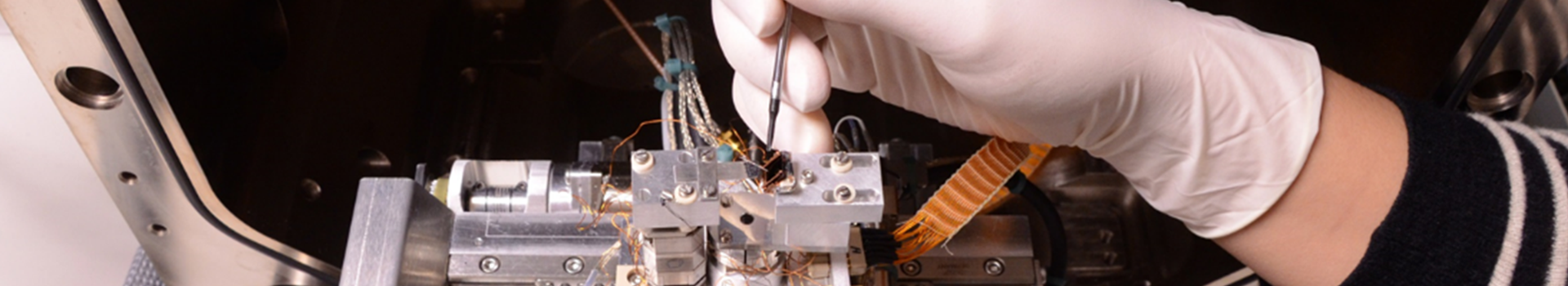

Simulations of a topological rearrangement in foams

The elementary process in the flow of a foam is a T1 event, a topological rearrangement involving the relative motion of bubbles which switch neighbours. Using level-set simulations that describe the interface and surfactant dynamics, we investigate the role of surfactants and find that their presence can change the nature of the flow from purely extensional to a shear.

Level-set simulations of a 2D topological rearrangement in a bubble assembly Titta et al., J. Fluid Mechanics (2018).

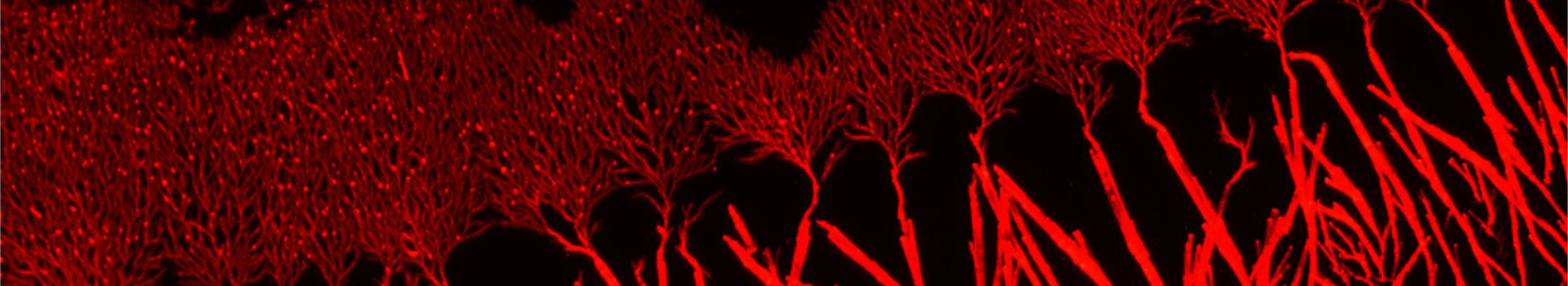

Confined flows of microgels

We study the breakdown of bulk rheology in confined flows of yield stress fluid made of highly entangled polymer microgels of Carbopol. Cooperative processes under flow are evidenced. We additionaly introduce an original optical microscopy method to access structural properties of the microgel. Overall, the combine static and dynamic characterization provides a strong grounding to the “Shear Transformation Zones” modeling approach.

Confined flows of a polymer microgel Géraud et al. EPJE (2013). Structural and cooperative length scales in polymer gels Géraud et al. EPJE (2017)

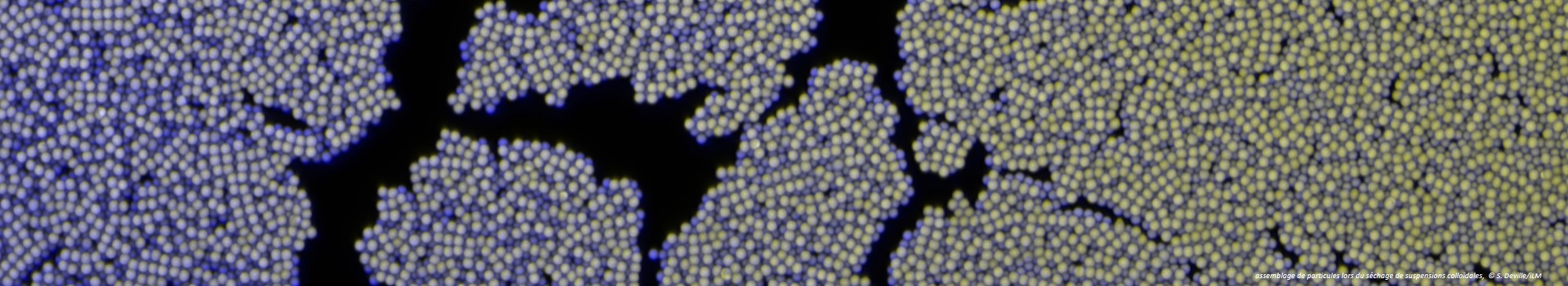

Colloidal rain

We study experimentally the process of gel formation in colloids, often described as a phase separation arrested by a glass transition. Here we found that the arrest can instead be due to crystallisation. The crystallisation proceeds by the same mechanism responsible for the formation of rain in clouds.

Formation of porous crystals via viscoelastic phase separation, Tsurusawa et al., Nature Materials (2017).

Elasticity and yielding of calcite paste

We characterize the rheology of suspensions of calcium carbonate to get information on the inter-particle interactions in this model system for cement. We found that the yield strain of the pastes exhibits a minimum versus concentration, a major prediction of colloidal-gel theory, never verified so far.

Elasticity and yielding of a calcite paste: scaling laws in a dense colloidal suspension, Liberto et al., Soft Matter (2017).

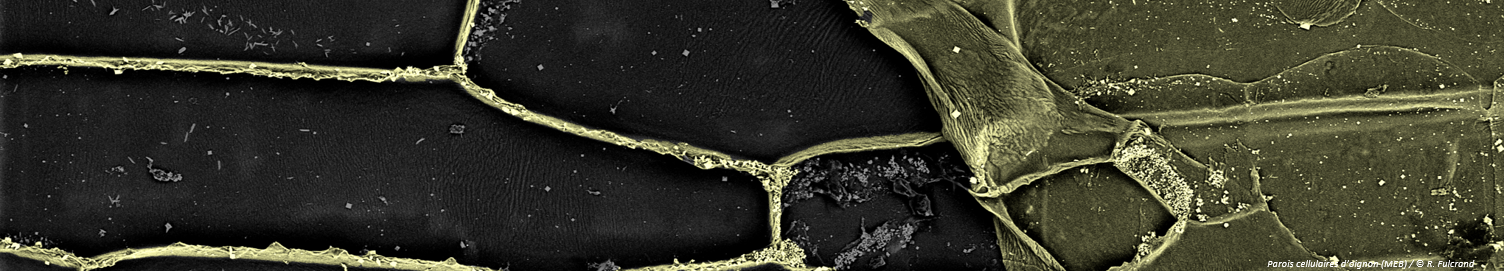

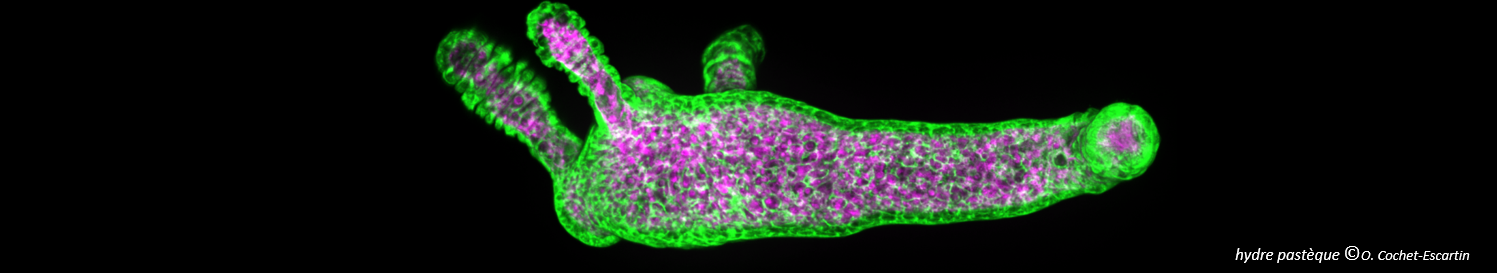

Wrinkling yoghurt

We study the wrinkling of a thin protein gel film (basically yoghurt) between two glass plates. pH-controlled contraction and swelling cause wrinkling. We show that the wavelength of the wrinkles is controlled dynamically either by the viscosity of the whey or by the porosity of the gel, two properties that have been overlooked so far in theoretical explanations of wrinkling. The results could be helpful to understand the physical forces that help shape the embryo.

Hierarchical wrinkling in a confined permeable biogel, Leocmach et al., Science Advances (2015).